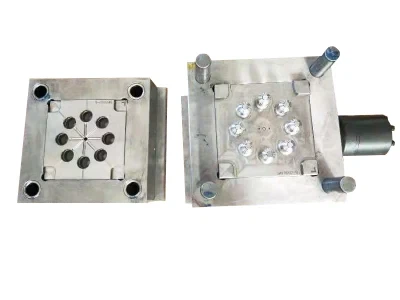

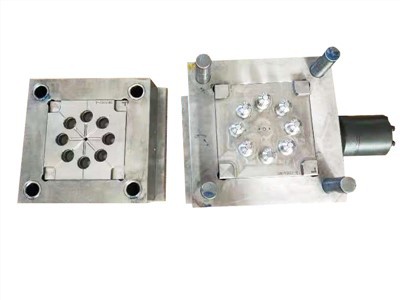

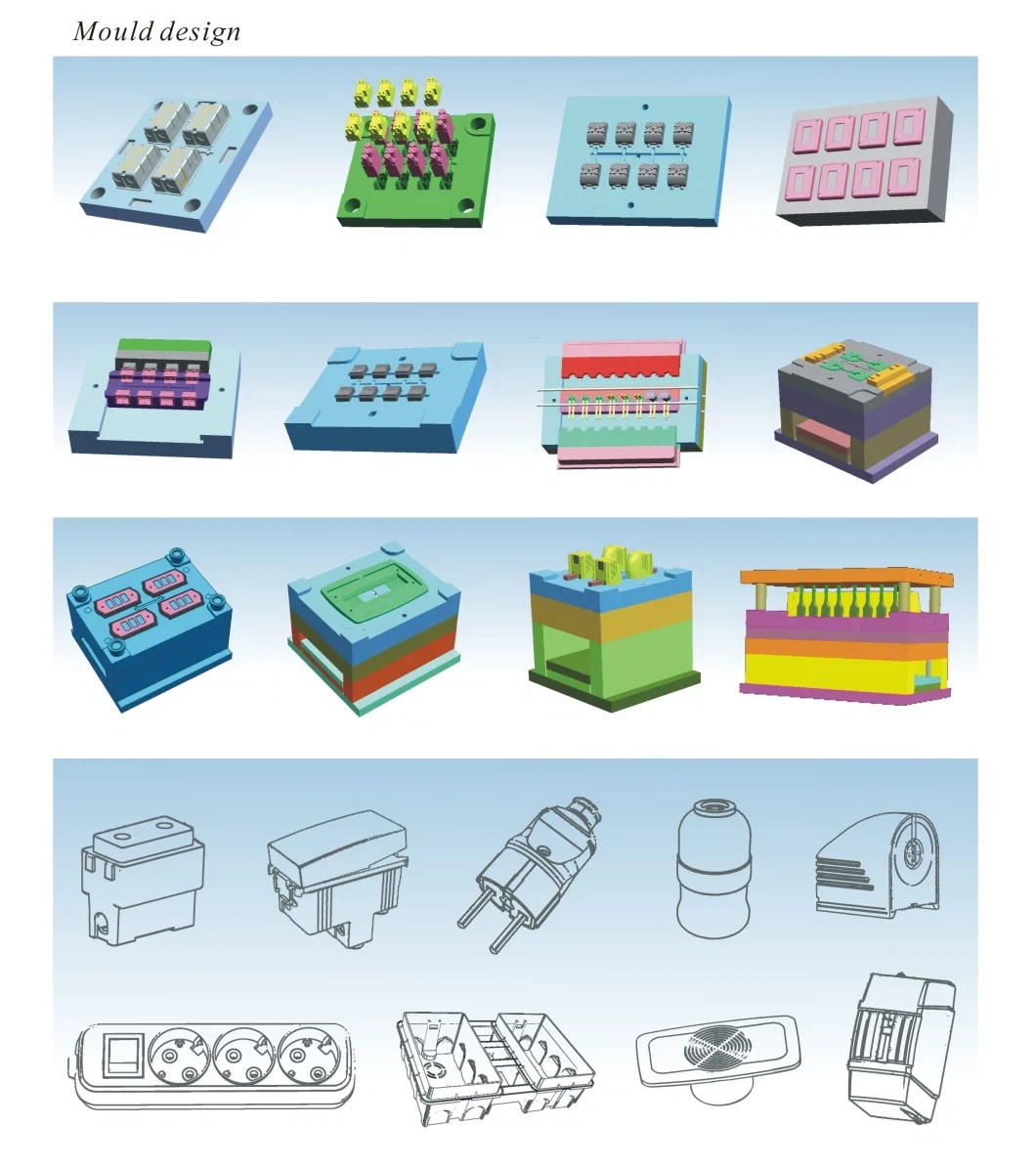

Plastic Injected Tooling

Mold Material: H13 or similar grade material

Key point on quality: more quantity for less cost

Short description: it is for big requirement. We have to design more piece for each part

Features

Plastic injected tooling is a tool manufacturing process that is vital to many industries worldwide. The process involves the use of a molding machine to melt plastic pellets to form a specific shape. The melted plastic is then injected into the mold cavity at high pressure, resulting in a solid object with precise dimensions and details.

As a manufacturer based in China, we specialize in the production and wholesale of plastic injected tooling to merchants in countries outside of China. Our company has over 10 years of experience in this industry and we have built a strong reputation for high-quality products and excellent customer service.

Our plastic injected tooling products are of exceptional quality because we use cutting-edge technology and high-quality materials to ensure that our products are durable and long-lasting. We use advanced software to design and test our tooling products, allowing us to create products that perfectly match the specifications and requirements of our clients.

One of the main advantages of using our plastic injected tooling products is their versatility. They can be used to create plastic components of varying complexities and sizes. Our products can be used to manufacture a wide range of items, including household products, automotive parts, medical equipment, and toys, among others.

When it comes to our products, we pride ourselves on our flexibility in meeting the unique needs of our clients. We take into consideration the specific requirements of each order, such as the type of plastic that should be used or the dimensions of the mold, to ensure that our products meet the highest standards.

We also offer a range of customization services that allow our clients to create unique products that match their requirements. Our team of expert engineers and technicians can provide design assistance and help customize tooling products to meet the specific needs of our customers.

Apart from our commitment to quality and customization, we also offer competitive pricing for our products. We are dedicated to providing our clients with the best value for their money, which is why we continuously seek out cost-effective solutions to minimize the cost of production while maintaining the quality of our products.

We understand that our clients place a high value on timely delivery, which is why we have optimized our production processes to ensure that we deliver our products on time. Our lead times are reasonable and competitive, and we provide regular updates to our clients throughout the production and delivery process.

In conclusion, we are a reliable and trusted manufacturer of plastic injected tooling products. Our products are of superb quality, versatile, and customizable, making them ideal for a wide range of applications. We are committed to providing our clients with competitive pricing, timely delivery, and excellent customer service. Contact us today to learn more about our products and services.

Mold Material:

H13 or similar grade material

Key point on quality:

More quantity for less cost

Description:

Plastic Injected Tooling

Quality:

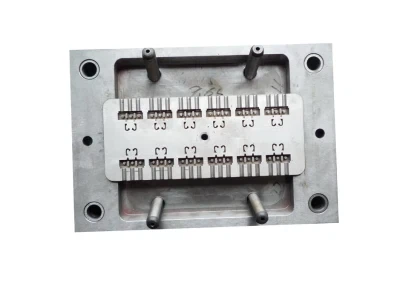

Design the good matching line to avoid the flash from design.

Quality control:

As there is many cavities for this model mold, we have to ensure all EDM part in suitable agreed size. If it failed, we will have more EDM part for finishing.

Mold details:

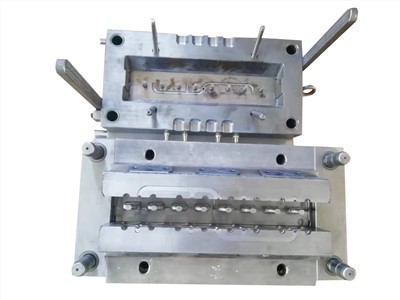

Mold should be design for stronger status, not just bigger. Also we should consider the runner design. If it is in cold runner, we have to ensure all product off 100%.

Mold structure:

2 big half sliding part

Injection machines size:

HAITIAN180KN. Injection material: PVC

About the injection material, the hardness is key factor. If it is too soft, the product will not off mold 100%.

Mold spare part for possible use:

Core part

Product itself:

PVC for plug, the design is for 6 cavities. For the injection gate point, it should have more care. As we must avoid the gate point hurt the customer finger. So we have to find some solution for this possible problem. Due to PVC material, it can not be off completely. So we have to find some corner for gate.

FAQ:

FAQ:

For Plastic Injected Tooling, if there is some problem during running, what shall I do ?

If you encounter problems during the operation of a plastic mold, there are several steps you can take to address the issue:

1. Identify the problem: First, you need to identify the issue you are experiencing with the plastic mold. Common problems can include defects in the finished product, uneven filling of the mold, and issues with the release of the final product from the mold.

2. Check the mold design: If you are experiencing problems with the finished product, you should review the mold design to ensure that it is properly designed for the intended product. This may involve adjusting the mold design or modifying the manufacturing process to achieve the desired results.

3. Inspect the mold: If you are experiencing issues with mold filling or product release, you should inspect the mold for any damage or wear. Mold damage can cause issues with product quality and may require repairs or replacement.

4. Adjust the process parameters: If you are experiencing problems with mold filling or product release, you may need to adjust the process parameters. This may include adjusting the temperature, pressure, or cooling time to achieve the desired results.

5. Clean and maintain the mold: Regular cleaning and maintenance of the mold can help prevent issues during operation. Ensure that the mold is properly cleaned and lubricated before each use, and regularly inspect the mold for any signs of wear or damage.

If you are unable to resolve the issue on your own, you may need to consult with a plastic mold expert or seek assistance from the manufacturer of the mold.

Why choose us?

- Our Plastic Injection Moulding products are designed to meet the unique needs and specifications of our clients in different industries.

- The attitude of taking every small step seriously and making all products extremely fine makes our final high-quality Plastic Injected Tooling highly recognized and well received by our customers.

- We provide exceptional customer service to our clients who choose us as their Plastic Injection Moulding supplier.

- Our company takes innovation and enterprising, honesty and mutual benefit as the principle and is famous for our high quality business positioning and integrity.

- We offer customized Plastic Injection Moulding solutions that cater to both small and large scale manufacturing needs.

- Our company is always full of passion and vitality, vibrant enterprise, and our staff feel honored to work together for the common cause and goal.

- We are committed to ensuring that every Plastic Injection Moulding product we produce meets our customers' specifications.

- We are a company with "integrity" "professional" as the purpose, "innovation" "professional" "difference" as the business philosophy of the company.

- Our cost-effective Plastic Injection Moulding solutions make us the go-to supplier for businesses of all sizes.

- We recruit talents to inject fresh blood into the development of the enterprise and enhance the forward momentum of the enterprise.

Hot Tags: plastic injected tooling, China plastic injected tooling suppliers, manufacturers, factory, Brass Plug Male Pin, Metal Electrical Parts, Turning For Electronics And Electrical Appliance, Precision Brass Part, Socket Precise Injection Mold, socket metal precise part

You Might Also Like

Send Inquiry