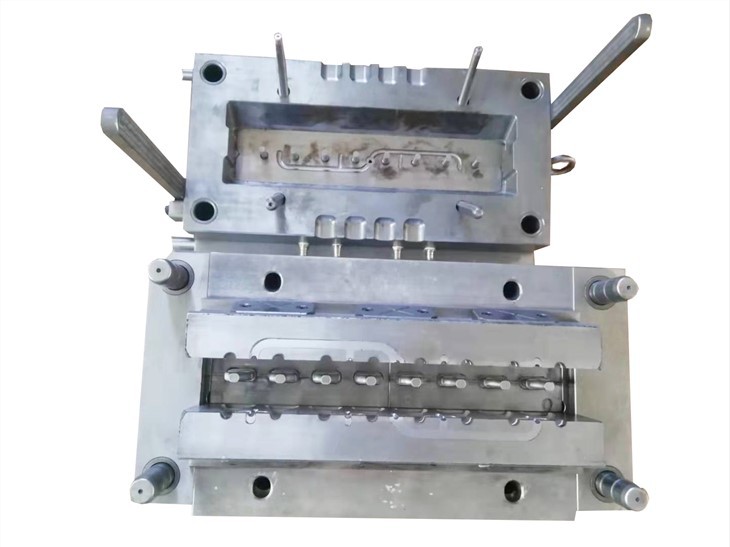

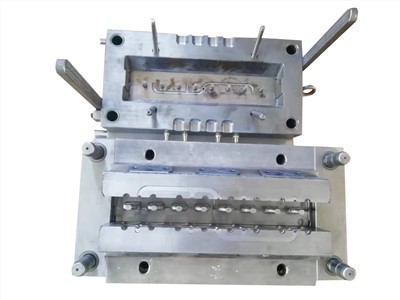

Switch Injection Mold

Plastic molds are crucial for quality plastic products. By focusing on their design, manufacturing, and maintenance, manufacturers can optimize their molding process and improve product consistency and quality.

Features

Switch Injection Mold is a premium quality product that is designed to meet the needs of manufacturers who seek efficient and reliable injection molding solutions. As a leader in the manufacturing of injection molds, we have invested heavily in technology and expertise to deliver the best quality products to our clients. Our molds are designed to meet the highest quality standards and are made using materials that are durable, reliable and long-lasting.

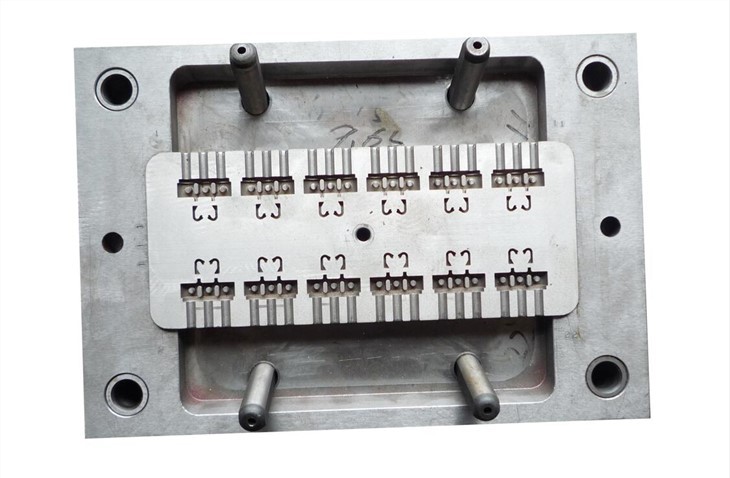

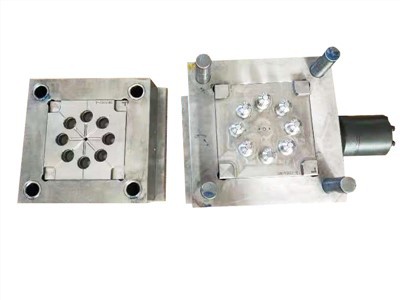

One of the key features of the Switch Injection Mold is its versatility. It can be used to manufacture a wide range of products, from small items such as automotive parts, to large components like home appliances. The mold is designed in such a way that it can produce products with high precision and accuracy, which ensures that your final product is of the highest possible quality.

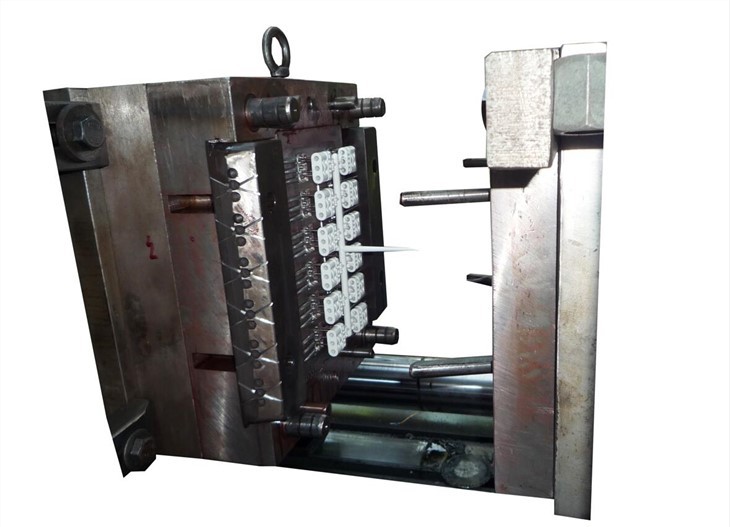

Another key feature of the Switch Injection Mold is its longevity. We use top-quality materials to manufacture our molds, which means that they have a long lifespan and are highly reliable. With proper maintenance, our molds can be used for years, which translates to higher profitability for your business.

To ensure the highest quality and consistency in our products, we carry out rigorous testing and inspections at every stage of the manufacturing process. Our experienced and highly skilled team of engineers and technicians work around the clock to ensure that each mold is built to the highest possible standard. We also use cutting-edge technology and state-of-the-art machinery to manufacture our molds, which enables us to deliver products that meet the most stringent quality requirements.

Another major advantage of the Switch Injection Mold is that it is highly customizable. We work closely with our clients to understand their exact requirements and tailor our molds to meet their specific needs. This level of flexibility ensures that you can create products that are unique to your business, which can set you apart from competitors.

We understand that time is a valuable commodity in today's fast-paced business environment. That's why we have a streamlined and efficient manufacturing process that enables us to deliver our products in a timely and cost-effective manner. Our priority is to ensure that our clients receive their products in a timely manner, without sacrificing quality or reliability. We pride ourselves on our ability to meet deadlines and provide products that meet or exceed our clients' expectations.

In conclusion, the Switch Injection Mold is a versatile, reliable and highly customizable product that is designed to meet the unique needs of businesses operating in the manufacturing industry. Whether you are a small or large-scale manufacturer, our molds can help you create high-quality products that meet the most stringent quality standards. From precision and accuracy, to flexibility and customizability, our molds offer unparalleled value to businesses looking to take their manufacturing processes to the next level. Contact us today to learn more about how our products can benefit your business.

Introduction to Switching Attention to Plastic Molds

Plastic molding is a crucial process in the manufacturing industry, enabling the creation of various plastic products such as toys, automotive parts, and medical devices. The plastic molds used in this process play a critical role in determining the quality and precision of the final product. Therefore, it is essential to pay close attention to the molds' design, manufacturing, and maintenance.

Switching attention to plastic molds involves a shift in focus from the final product to the molds themselves. This approach emphasizes the importance of the molds' quality and how it affects the final product's quality. By paying attention to the molds, manufacturers can optimize the molding process and improve their product's consistency and quality.

Designing a plastic mold requires careful consideration of various factors such as material selection, cooling systems, and gate design. The mold's quality also depends on the precision and accuracy of the manufacturing process. Precision machining techniques such as CNC (Computer Numerical Control) milling and EDM (Electrical Discharge Machining) are essential in producing molds with high accuracy and surface finish.

Maintaining plastic molds is also critical in ensuring their longevity and optimal performance. Regular cleaning, inspection, and repair of molds can prevent defects and ensure consistent product quality. Additionally, using high-quality materials and lubricants can extend the mold's lifespan and reduce downtime due to maintenance issues.

In conclusion, switching attention to plastic molds is an essential practice for manufacturers looking to optimize their plastic molding process and produce high-quality products consistently. Paying attention to the molds' design, manufacturing, and maintenance can lead to improved product quality, increased efficiency, and reduced costs in the long run.

Why choose us?

- Our Plastic Injection Moulding services are flexible, and we can accommodate even the most complex client demands.

- We provide a broad platform for our employees to give full play to their strengths and specialties to achieve a win-win situation for both companies and individuals.

- We are committed to continuous improvement and strive to exceed our clients' expectations with our Plastic Injection Moulding products and services.

- We insist on operating in accordance with the law, act in accordance with market rules, and regard credibility as the life of the company.

- By using superior materials, we ensure that our Plastic Injection Moulding products are durable and long-lasting.

- In order to better guarantee the quality of products, the company has invested a lot of money and established a complete testing method.

- Our Plastic Injection Moulding factory boasts state-of-the-art technology that guarantees the exceptional quality of our products.

- We will provide good quality Switch Injection Mold with fast and caring service as always, and will sincerely cooperate with old and new customers to create a better tomorrow together!

- Our Plastic Injection Moulding services are customized to meet the unique requirements of our clients.

- For many years, our company has focused on the manufacture of Switch Injection Mold and is one of most competitive suppliers in China.

Hot Tags: switch injection mold, China switch injection mold suppliers, manufacturers, factory, socket brass stamping part, Precise Plastic Parts For Machines, Holder With Thread Injection Mold, Product Assembly, Brass Plug Pins Flat, Wiring Device Injection Mold

You Might Also Like

Send Inquiry