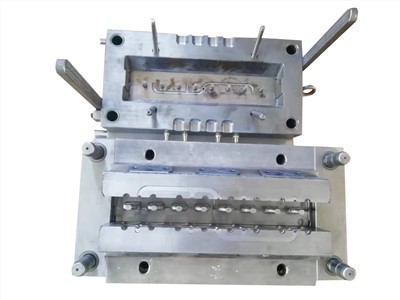

Electrical Product Mold

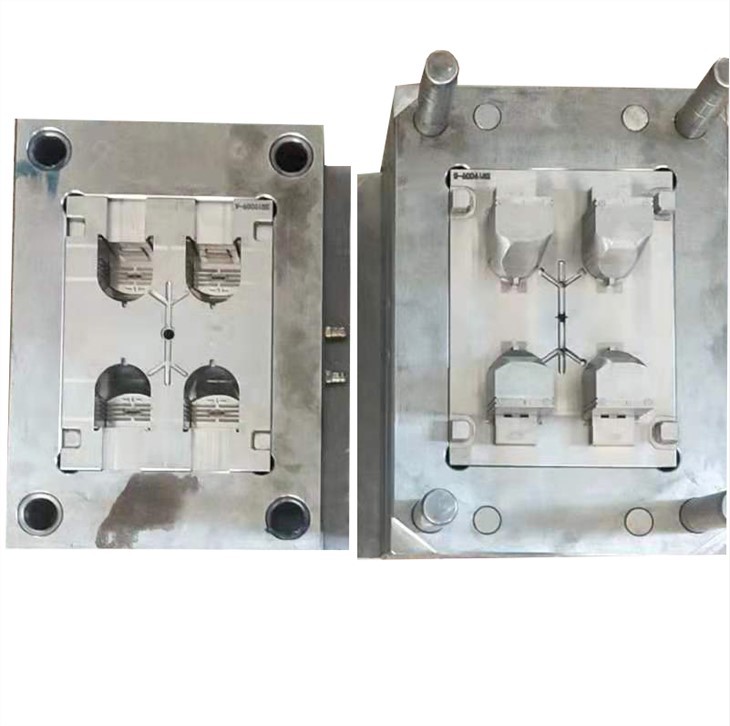

Introduction to Molds for Electrical Products Molds for electrical products play a vital role in the manufacturing process of various electrical components such as switches, sockets, and circuit breakers. These molds are essential for producing high-quality components that meet industry...

Features

Introduction:

Hello, and welcome! As a manufacturer of electrical product molds, we are excited to introduce our product to merchants. Our team is dedicated to providing high-quality products and excellent service to ensure that our customers are satisfied with their purchases. We believe that our electrical product mold is the perfect choice for merchants looking for a reliable and durable product that can help them create innovative and unique electrical products.

Product Description:

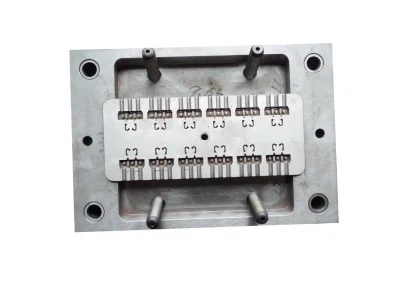

Our electrical product mold is made from high-quality materials that have been thoroughly tested to ensure their durability and functionality. The mold is designed for electrical products and is capable of producing different sizes and shapes of products. It is versatile and can be used to make a wide range of electrical products, including but not limited to electrical connectors, cable connectors, and terminal blocks.

Features & Benefits:

One of the most significant benefits of our electrical product mold is its versatility. It can be used to create different types of electrical products, making it an ideal choice for merchants who need a high-quality and multipurpose mold. The following features also make our electrical product mold an attractive choice for merchants:

1. Customizable

Our electrical product mold is customizable, which means that merchants can tweak the mold according to their specific needs. This aspect of our mold makes it a great choice for merchants who want to create unique products that stand out from their competitors.

2. High-Quality Materials

Our electrical product mold is made from high-quality materials that have been rigorously tested to ensure their durability and strength. This aspect of our product ensures that merchants can trust in the longevity and reliability of the mold.

3. Easy to Use

Our electrical product mold is easy to use, and merchants will not need any special skills or knowledge to operate it. This aspect of the mold makes it a great choice for merchants who want a user-friendly and straightforward product.

4. Cost-Effective

Our electrical product mold is also cost-effective, meaning that merchants can save money while also receiving a high-quality product. This aspect of the mold makes it an attractive choice for merchants who want to create quality electrical products without breaking the bank.

Usage and Applications:

Our electrical product mold can be used to produce different electrical products, including but not limited to electrical connectors, cable connectors, and terminal blocks. The mold is versatile and can be tweaked to create unique and innovative products. The possibilities are endless! Merchants can use this mold to create different sizes and shapes of electrical products, making it an ideal choice for those who want to offer a broad range of products to their customers.

Conclusion:

In conclusion, our electrical product mold is a high-quality, versatile, customizable, easy-to-use, and cost-effective product. We are confident that merchants will find our mold an excellent choice for creating innovative and unique electrical products that stand out from the competition. If you are looking for a reliable and durable electrical product mold, look no further. Our team is dedicated to providing excellent service and high-quality products to our customers, and we guarantee satisfaction with every purchase. Thank you for considering our product, and we look forward to hearing from you soon!

Introduction to Molds for Electrical Products

Molds for electrical products play a vital role in the manufacturing process of various electrical components such as switches, sockets, and circuit breakers. These molds are essential for producing high-quality components that meet industry standards and customer requirements.

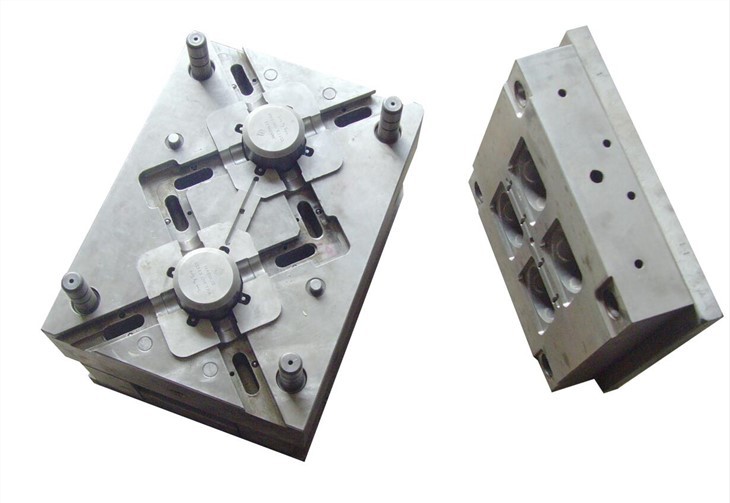

Designing molds for electrical products requires careful consideration of various factors, such as material selection, dimensional accuracy, and surface finish. The molds must be designed to produce components with specific electrical and mechanical properties, such as conductivity and strength. They must also be designed to meet safety requirements, ensuring that the final product can withstand high voltage and extreme conditions.

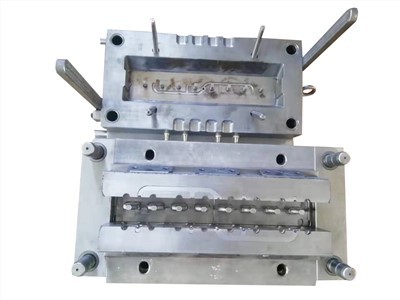

The manufacturing process for molds for electrical products is complex and requires expertise in precision engineering and materials science. Advanced machining techniques, such as CNC (Computer Numerical Control) milling and wire EDM (Electrical Discharge Machining), are used to produce molds with high dimensional accuracy, surface finish, and stability.

Maintenance of molds for electrical products is critical in ensuring their longevity and optimal performance. Regular cleaning, inspection, and repair of molds can prevent defects and ensure consistent product quality. Using high-quality materials and lubricants can also extend the mold's lifespan and reduce downtime due to maintenance issues.

In conclusion, molds for electrical products are essential for producing high-quality components that meet industry standards and customer requirements. By paying attention to their design, manufacturing, and maintenance, manufacturers can optimize their production process and ensure the consistency and quality of their products.

Why choose us?

- Our experienced team of engineers designs and develops top-quality Plastic Injection Moulding products that are durable and reliable.

- Looking forward to the future, all employees of our company will work hard, forge ahead, and strive to bring more high-quality products to customers.

- We provide exceptional customer service to our clients who choose us as their Plastic Injection Moulding supplier.

- We have a professional R&D system with advanced production and quality testing equipment to produce perfect Electrical Product Mold.

- Our team of skilled technicians uses innovative approaches to produce top-quality Plastic Injection Moulding products.

- We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers.

- Our Plastic Injection Moulding products and services are trusted by clients across various industries, including electronics, packaging, and construction.

- We try to eliminate all possible waste and leakage, simplify everything, and take the best as our ultimate goal.

- Our team of experts employs the latest technology and tools to create superior Plastic Injection Moulding molds.

- Our company draws lessons from the advanced management concept and mode, actively integrates and innovates, continuously improves the management level and efficiency and continuously enhances the operation ability.

Hot Tags: electrical product mold, China electrical product mold suppliers, manufacturers, factory, Precise Plastic Parts For Machines, Brass Electrical Switch Parts, Switch Precise Injection Mold, Brass Plug Pins Flat, socket brass stamping part, Wiring Device Metal Part

You Might Also Like

Send Inquiry