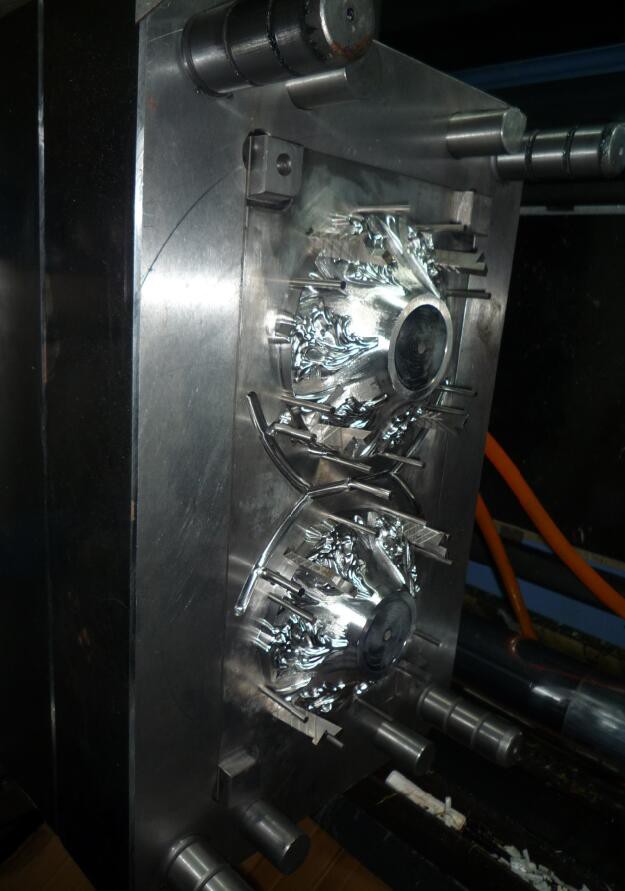

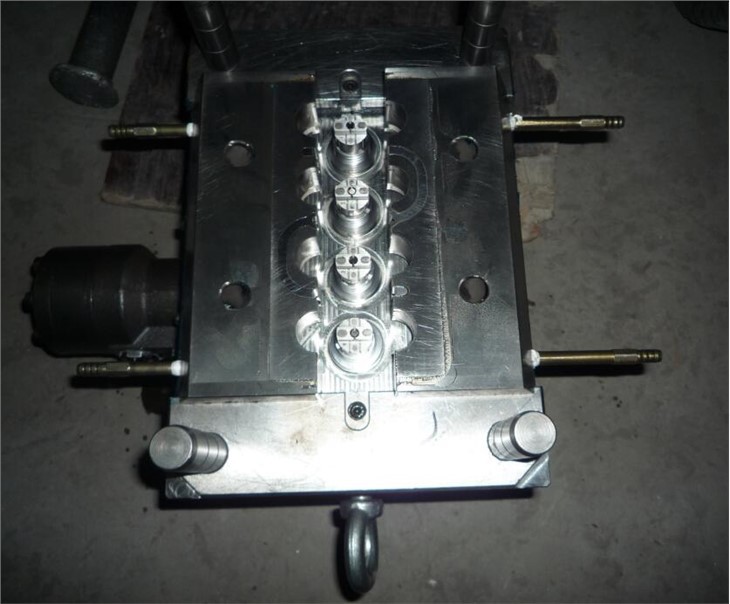

Lampholder Mold

A lampholder mold is a specialized tool used in the manufacturing of lampholders, which are devices that hold light bulbs in place. The mold is made of high-quality materials, such as steel or aluminum, and is designed to create the specific shape and size of the lampholder. The mold is...

Features

.

Introduction:

As a leading manufacturer of quality products in China, we are proud to introduce our latest creation - Lampholder Mold. This product is designed to cater to the unique needs of merchants worldwide who are looking for innovative, effective, and efficient solutions to meet their customers' demands. We understand that product quality is of utmost importance, and that is why we have spared no effort in ensuring that our Lampholder Mold meets the highest quality standards possible.

Key features:

Our Lampholder Mold boasts of various features that make it stand out from the crowd. Here are some of the key features merchants can look forward to when they purchase our Lampholder Mold:

1. High-quality material: Our Lampholder Mold is made of the finest materials, ensuring durability, strength, and reliability.

2. High Precision: We use the most advanced manufacturing techniques to ensure that our molds have high precision, so our clients can produce high-quality products that meet or exceed industry standards.

3. Custom engraving: We offer custom engraving services to allow for customized branding to tailor your products.

4. High Efficiency: Our molds are designed to be highly efficient, saving time and money for the manufacturers, and providing a seamless and effective production line for the merchants.

5. Cost-effective: We offer our Lampholder Mold at very competitive prices, so merchants can save money while still getting a high-quality product.

Applications:

Our Lampholder Mold is suitable for several applications across various industries, including electrical and lighting. We can design and manufacture different types of molds that can produce various shapes, sizes, and materials to meet different needs. Some of the uses of our Lampholder Mold include:

1. Production of high-quality and efficient lighting fixtures.

2. Development of customized electrical fittings for various applications, including automotive and aerospace industries.

3. Manufacturing of detailed plastic parts that require high precision, accuracy, and reliability.

Customer Benefits:

Merchants who choose to purchase our Lampholder Mold can expect to receive several benefits, including:

1. High precision production: With our molds, merchants can expect to produce products of high precision, accuracy, and consistency.

2. Improved efficiency: Our molds are designed to be highly efficient, saving time and money for the merchants and increasing productivity.

3. Cost-effective: We strive to offer our products at much more affordable prices than what our competitors offer.

4. Professional support: We have a dedicated customer support team that ensures utmost client satisfaction at all times.

Conclusion:

In summary, our Lampholder Mold represents the highest quality standard for merchants seeking innovative and effective solutions for their customers' needs. With numerous benefits and features, we aim to provide the best in quality, durability, and reliability to our clients. We invite all interested merchants to contact us to learn more about our Lampholder Mold and the many other innovative products we offer. We look forward to doing business with you.

A lampholder mold is a specialized tool used in the manufacturing of lampholders, which are devices that hold light bulbs in place. The mold is made of high-quality materials, such as steel or aluminum, and is designed to create the specific shape and size of the lampholder. The mold is typically created using precision machining techniques, which ensure that each mold is identical and produces consistent results.

The lampholder mold is a critical component in the manufacturing process, as it allows for the production of high-quality and uniform lampholders. The mold is typically operated using a molding machine, which heats and injects the molten material into the mold cavity. Once the material has cooled and solidified, the mold is opened and the finished lampholder is removed.

The design of the lampholder mold can vary depending on the specific requirements of the lampholder being produced. For example, some molds may be designed to create lampholders with specific features or shapes, while others may be used to produce lampholders in large quantities.

Overall, the lampholder mold is a crucial tool in the manufacturing of high-quality lampholders. Its precision design and construction ensure that each lampholder is produced to the exact specifications required, and it is a key component in the overall production process.

Why choose us?

- Our Plastic Injection Moulding services are customized to meet the unique requirements of our clients.

- We adhere to the concept of taking the green development path, open cooperation and win-win development.

- Our team of skilled technicians uses innovative approaches to produce top-quality Plastic Injection Moulding products.

- With our strong business integration and resource integration capabilities, we have vigorously implemented the strategy of going global.

- Our Plastic Injection Moulding products and services are trusted by clients across various industries, including electronics, packaging, and construction.

- By achieving a complete set of effective design and quality control from raw materials to final product, we are able to provide our customers with the highest quality Lampholder Mold in the shortest possible time and at competitive prices.

- We are a Chinese factory that specializes in producing high-quality Plastic Injection Moulding products.

- We always practice the principle of integrity-based and win-win cooperation, insist on first-class quality as the cornerstone of our business, and escort the enterprise with quality service and technological innovation.

- We use the best materials available in our Plastic Injection Moulding processes to ensure that our products are of superior quality.

- Before sales, we will provide you with professional technical consulting services, such as product performance, characteristics, drawings, etc.

Hot Tags: lampholder mold, China lampholder mold suppliers, manufacturers, factory, Brass Terminal Blocks, Electrical Stamping Part, Metal Stamping Part, Brass Electrical Component, Copper Electrical Components, Brass Neutral Links

You Might Also Like

Send Inquiry