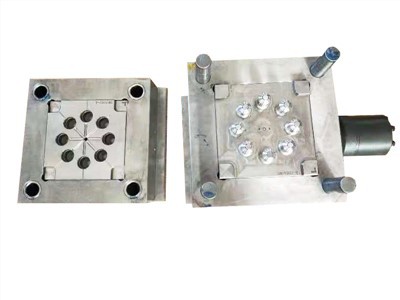

Plug Injection Mold

Plug injection molding is a specialized technique used in the manufacture of injection molded parts. It involves the use of a plug, which is a small piece of plastic or metal that is inserted into the mold cavity before the injection process begins. The plug serves as a barrier between the mold...

Features

Introduction

As a leading manufacturer in China, we specialize in supplying high-quality products to merchants in countries outside of China. Our latest product, Plug Injection Mold, is a must-have for businesses requiring reliable, efficient, and cost-effective plug manufacturing solutions. From electronics to automobiles, our Plug Injection Mold is a versatile product that can fit the needs of any industry. In this article, we will delve into the different aspects of Plug Injection Mold to help you understand its features and benefits, as well as showcase why it is the perfect product for your business.

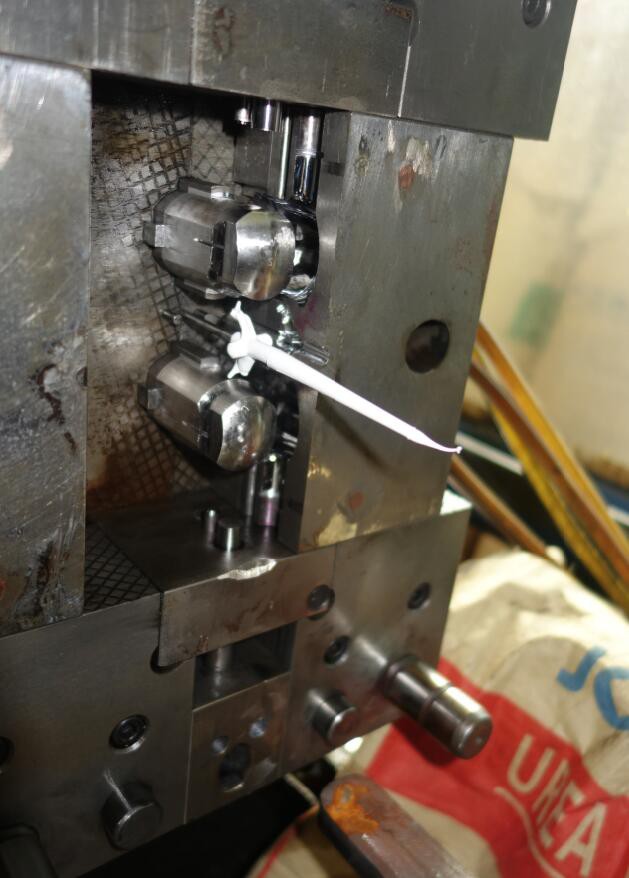

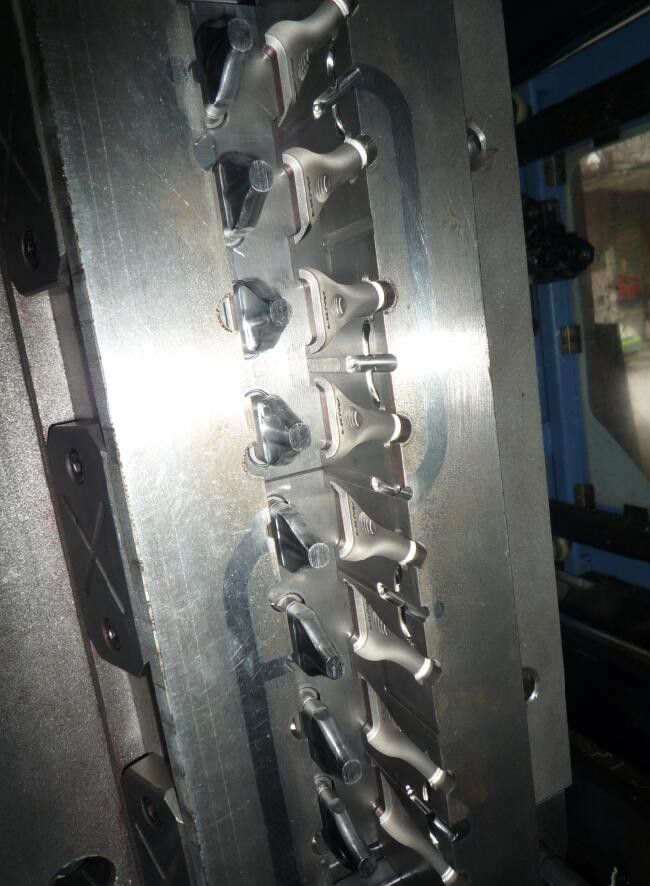

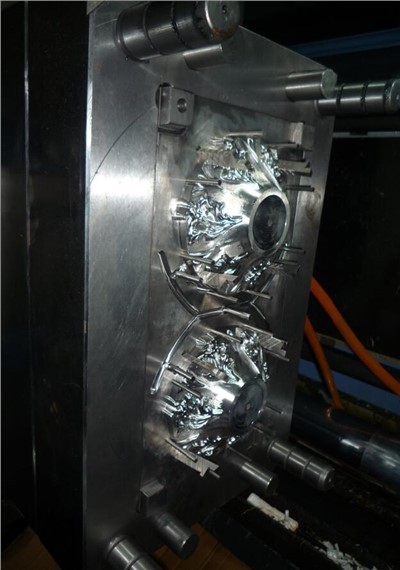

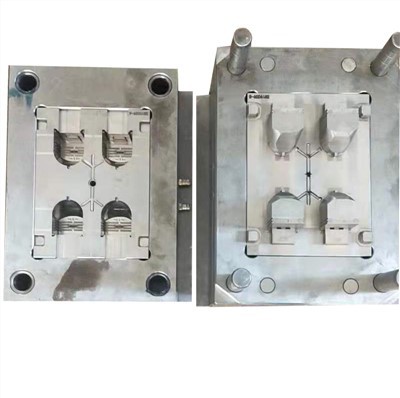

Product Description

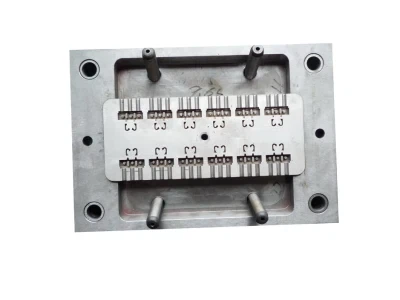

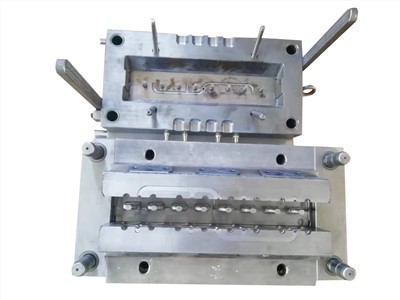

Our Plug Injection Mold is designed to manufacture high-quality plugs that are used in various devices and appliances. It is made from high-quality materials that ensure the longevity of the product and the precision in molding plugs. The mold is versatile and can be customized according to the client's specifications, whether through changing the size of the mold or adjusting the materials used.

Features

1. Versatility - Our Plug Injection Mold can be used to manufacture a variety of plugs that vary in size, shape, and material. This makes it an excellent product for businesses looking for customized plug solutions.

2. Durability - We use the highest quality materials to ensure that our product can withstand constant use and abuse in a manufacturing environment.

3. Precision - Our Plug Injection Mold is designed to produce plugs with exact specifications, making it the perfect choice for businesses that require consistency and accuracy in their products.

4. Cost-Effective - By using our Plug Injection Mold, businesses can save money on their manufacturing costs and increase their profitability.

Benefits

1. Customizable - Our Plug Injection Mold is easily customizable, allowing businesses to design and manufacture plugs that meet their specific needs.

2. High-Quality - Our product is made from high-quality materials and is designed to produce high-quality plugs, ensuring the longevity and reliability of the products that businesses manufacture.

3. Consistency - Our mold ensures consistent quality and accuracy in each plug it produces, which guarantees that each product manufactured is of the highest quality.

4. Efficiency - Our Plug Injection Mold is designed to improve the efficiency of the manufacturing process, which reduces the time and money spent on producing products.

Conclusion

In conclusion, our Plug Injection Mold is a reliable, efficient, and cost-effective solution for businesses needing custom plugs. Our product is versatile, durable, and designed to produce high-quality plugs, allowing businesses to enhance their manufacturing processes and increase profitability. As a leading manufacturer in China, we strive to provide exceptional products and services to our clients, and our Plug Injection Mold is no exception. Contact us today to learn more about our product and how it can improve your business's manufacturing process.

Plug injection molding is a specialized technique used in the manufacture of injection molded parts. It involves the use of a plug, which is a small piece of plastic or metal that is inserted into the mold cavity before the injection process begins.

The plug serves as a barrier between the mold cavity and the injection nozzle, preventing the molten plastic from flowing into the cavity before the plug is removed. This allows for the creation of multi-material parts with different colors, textures, and mechanical properties in different areas of the same part.

Plug injection molding is often used in the automotive, electronics, and consumer goods industries, where parts with complex geometries and multiple materials are required. It is also used in the medical industry, where parts with high precision and cleanliness standards are necessary.

The plug itself can be made from a variety of materials, including plastic, metal, or ceramic, depending on the requirements of the application. It is typically designed to be easily removed from the mold cavity after the injection process is complete.

To create a plug injection molded part, the mold is first prepared with the plug in place. The molten plastic is then injected into the mold cavity through the injection nozzle, filling the space around the plug. Once the plastic has cooled and solidified, the plug is removed, leaving behind a part with the desired shape and properties.

Overall, plug injection molding offers manufacturers a highly flexible and versatile method for producing complex parts with multiple materials. Its ability to create precise and unique parts makes it a valuable technique for a variety of industries.

Why choose us?

- Our manufacturing processes ensure that our Plastic Injection Moulding products are consistently of the highest quality.

- We follow the scientific concept of sustainable development and create a core culture of positive energy.

- Our team of experts employs the latest technology and tools to create superior Plastic Injection Moulding molds.

- Our business model starts with providing us with brand innovation consumer insights, usually with our partners in the supply chain using brand innovation to create products that we bring to the market.

- Our experienced team of engineers designs and develops top-quality Plastic Injection Moulding products that are durable and reliable.

- It is because of the understanding and tolerance of our customers that we can continuously improve the quality of our Plug Injection Mold] and services in the process of correcting deficiencies and accumulating experience.

- Our Plastic Injection Moulding production processes are environmentally friendly, and we strive to minimize our impact on the environment.

- We believe that China's traditional culture and macro environment can nurture excellent enterprises with distinctive culture.

- Our Plastic Injection Moulding products are designed to meet the unique needs and specifications of our clients in different industries.

- Facing the new chance for development, the company will cooperate with friends in all circles with best quality products, promptest shipment and most competitive price as ever.

Hot Tags: plug injection mold, China plug injection mold suppliers, manufacturers, factory, switch contact, Socket Precise Injection Mold, Phosphor Stamping Part, Brass Electrical Pins, Wiring Device Metal Part, Copper Electrical Components

You Might Also Like

Send Inquiry