Switch Socket Injection Mould

Socket Mold is a type of injection mold used for manufacturing various types of sockets, including electrical switch sockets, computer sockets, and phone jacks. The mold is designed to produce sockets with precise dimensions and smooth surfaces, ensuring that the final product meets the required...

Features

Switch Socket Injection Mould - The Ideal Choice for Home and Office

Are you looking for a reliable and high-quality switch socket injection mould? Look no further than our products, made with the finest materials and technology to meet the highest standards of safety and durability. As a leading manufacturer based in China, we provide a wide range of injection moulds that can be used for various kinds of switches and sockets, fitting the needs of different customers from all over the world.

Features and Benefits

Our switch socket injection moulds are characterized by the following features and benefits:

1. High Precision and Durability: Our moulds have a high level of accuracy and precision that ensures the product is always of high quality. We use materials such as die steel, mold steel, and stainless steel that guarantee the durability of the moulds in the long run.

2. Easy to Use: Our moulds are easy to use and require low maintenance. Operators only need to replace the mould for different products and can operate the machine with ease.

3. Flexibility: One mould can produce various kinds of switch sockets, reducing the cost of production and making it an ideal choice for customers who require large scale production.

4. High Efficiency: Our injection moulds are designed to be efficient and consume less energy, consequently reducing the cost of production for our clients.

5. Customization: We can also customize the mould to the specifications required by our clients, including the logo, design, dimension, and material.

Why Choose Our Switch Socket Injection Moulds?

There are several reasons why our company is the ideal choice for customers looking for switch socket injection moulds. Here are a few examples:

1. Quality Control: We conduct a stringent quality control process that ensures our products meet the highest standards of safety and durability. Our moulds go through a process of testing, inspection, and certification to ensure optimal performance.

2. Cost-effective: Our moulds are competitively priced, giving customers the opportunity to enjoy high-quality products at affordable rates, while maximizing value for money.

3. Customer Service: Our team of experts is available to provide excellent customer service, answering any questions, and offering solutions to clients' needs.

4. Quick Production and Delivery: We understand the importance of timely delivery, and we strive to meet deadlines without compromising quality.

5. Experience: Our company has been in the injection mould industry for years and has been providing quality products to customers from all over the world.

Conclusion

Our switch socket injection moulds are the ideal choice for customers looking for a reliable, durable, and cost-effective product. With a focus on quality control, customer service, and timely delivery, we ensure that our clients receive only the best products at competitive prices. Contact us today for more information on how we can provide you with a solution to your switch socket injection mould requirements.

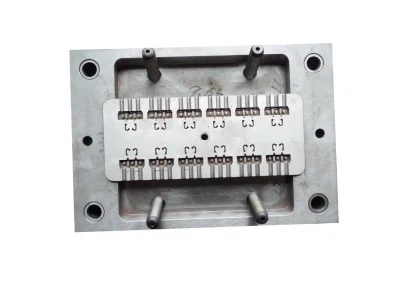

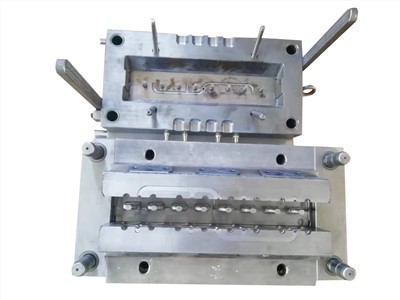

Socket Mold is a type of injection mold used for manufacturing various types of sockets, including electrical switch sockets, computer sockets, and phone jacks. The mold is designed to produce sockets with precise dimensions and smooth surfaces, ensuring that the final product meets the required specifications.

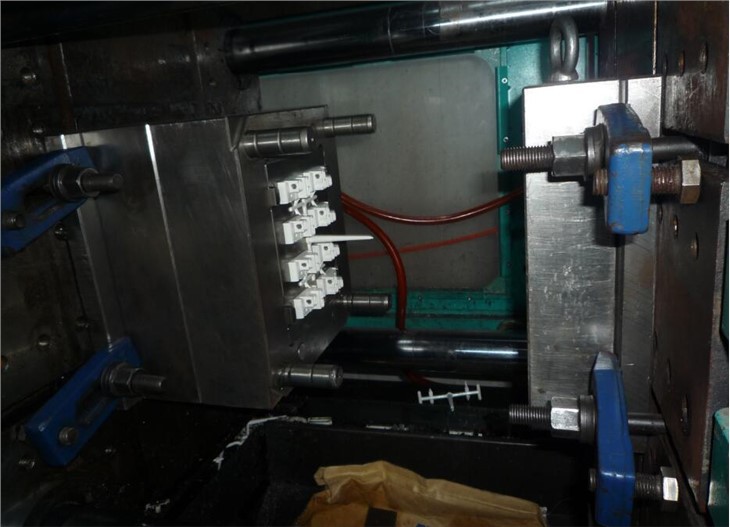

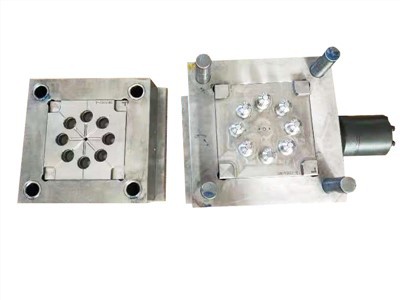

The mold is typically made of high-quality steel, which is resistant to wear and tear and can withstand high temperatures and pressure. The mold is composed of several parts, including the core, cavity, and runner system. The core and cavity create the shape and size of the socket, while the runner system is used to channel the molten material into the mold.

The process of manufacturing sockets using this mold begins with the melting of the raw material, which is usually plastic, in a heated barrel. The molten material is then injected into the mold through the runner system under high pressure. The material then cools and solidifies inside the mold, taking the shape of the core and cavity.

After the material has solidified, the mold is opened, and the newly formed socket is ejected from the cavity. The socket is then trimmed and cleaned, ready for use in various applications.

Socket Mold is an essential tool for the production of high-quality sockets used in various industries, including electronics, telecommunications, and home appliances. Its precision and durability make it a preferred choice for manufacturers looking to produce large quantities of sockets efficiently and cost-effectively. The mold can be customized to meet specific requirements, making it a versatile tool for various applications in the manufacturing industry.

In summary, Socket Mold is a complex and precise mold used for the production of various types of sockets. Its high-quality construction and efficient production process make it a valuable tool for manufacturers looking to produce sockets that meet strict quality standards.

Why choose us?

- We offer end-to-end Plastic Injection Moulding solutions, from design and development to production and delivery.

- We pay attention to the cultivation and development of employees who are "courageous, think and act well, loyal and dedicated, and technically mature".

- We provide exceptional customer service to our clients who choose us as their Plastic Injection Moulding supplier.

- The company is committed to industrial ecological construction and business model innovation, and has become a global Switch Socket Injection Mould integrated solution service provider that creates long-term value for customers.

- Our Plastic Injection Moulding factory is equipped with modern equipment and machinery to produce high-quality plastic products.

- We constantly strengthen the attraction and development of talents to better provide strong talent support for enterprise development.

- Our Plastic Injection Moulding services are designed to streamline the manufacturing process and reduce costs for our clients.

- Cooperation is mutual help rather than mutual use, sincere collaboration rather than exchange of benefits.

- Our talented team of professionals is dedicated to providing the best Plastic Injection Moulding products and services in the industry.

- We hope that more customers can provide high-quality Switch Socket Injection Mould and win the trust and praise of customers.

Hot Tags: switch socket injection mould, China switch socket injection mould suppliers, manufacturers, factory, Wiring Device Injection Mold, Electric Pin For Plug, Brass Neutral Links, Electrical Appliance Injection Mold, Wiring Device Metal Part, socket brass stamping part

You Might Also Like

Send Inquiry