Maintenance of the stripper of continuous die for metal stamping

Metal stamping continuous die:

It refers to a stamping tool that is fixed on a punch press and exerts a certain pressure on metal or non-metal plates to separate or shape the material.

For the maintenance of the stripper plate of the continuous metal stamping die, the force should be applied evenly when the mold is demolished. For the mold structure on the inner guide column, the stripper plate should be removed to ensure that the stripper plate is balanced and ejected. The inclination of the stripper plate may cause Breaking of the punch in the mold.

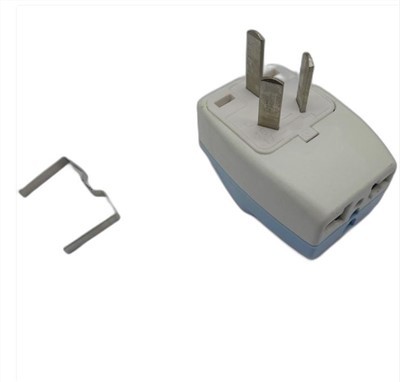

The disassembly of the stripper plate of the metal stamping continuous die:

To disassemble the stripper plate of the continuous metal stamping die, first use two screwdrivers to balance the prying, and then use both hands to balance the force and take it out. When it is difficult to disassemble, make sure that the inside of the mold is cleaned up, and the locking screws must be disassembled. If the mold is damaged due to material jams, find out the reason and do the corresponding treatment, and do not blindly dispose of it.

Assemble the stripping board:

When assembling the stripper plate, first clean the punch and stripper plate, add lubricating oil to the guide post and the insertion place of the punch, put it in steadily, and then press it in place with both hands, and repeat it several times. If it is too tight, find out the reason (whether the guide post and the guide sleeve are oriented normally, whether there are damages in various parts, whether the new punch can pass the stripper plate smoothly, and whether the position is correct), and then deal with it accordingly.

Give way to the stripper:

If there is a press block on the fixed plate, check whether the clearance on the stripping back plate is sufficient. The material contact surface between the stripper plate and the die is stamped for a long time to produce indentation. When the indentation is serious, it will affect the pressing accuracy of the material and cause the product size to be abnormally unstable. Repair or re-grind. The contour sleeve should be checked for accuracy. If it is not equal in height, it will cause the stripper plate to tilt, and the precision guiding and smooth spring pressing function of the continuous metal stamping die will be damaged and must be maintained.