Why do metal stamping parts cause tearing?

The common tearing and skewing forms of metal stamping parts. The stamping process of the middle protective surface bracket is: blanking and punching-punching incision-flanging forming-incision-flanging. There are many forms of tearing and skew during the forming process of the middle protective surface bracket. The tearing parts are mainly distributed at the hole pattern of the workpiece, and the R arc at the corner of the side wall and the junction of the wall neck, etc., due to stamping and production The difference in process conditions, the proportion of each fractured part is different. The tear can be a one-time forming tear, or a tear caused by the development of fatigue cracks, that is, invisible cracks.

Reason analysis: According to the actual situation of the site, by inspecting the tearing position, fracture shape and degree of crushing of the part, it is believed that the tearing and skewing behavior of the part is mainly reflected in the flanging forming process. The reasons for this process are as follows :

1. The forming process parameters are not in place. During the forming of the part, the process requires that the die, the pressing core and the two parts must be closely attached to each other, and the plastic deformation of the sheet material is forced when the machine tool slides down. Formed. However, due to the disadvantages such as unstable quality of the pressed parts, it shows that the pressure of the machine tool is in an unbalanced state of pressure fluctuation during the production process. The main reason is that the processing technicians did not adjust the pressure of the machine tool at this stage in time according to the requirements of the process designation, or did not communicate the machine pressure stability information with each other during the handover of each shift, resulting in poor quality of the parts. Stablize.

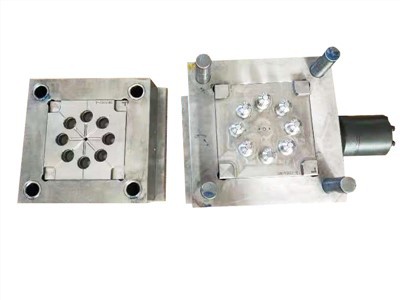

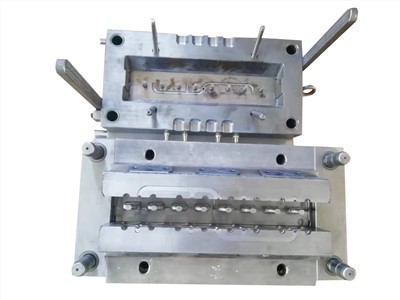

2. Defects in the design of the flanging forming mold. The mold is shared for the left and right parts of a mold with two cavities. Because the content of this process is not only the flanging, but also the shape forming content. In addition, the parts are particularly complex, the curved surface is narrow, and the forming requirements are concave. The mold pressing material core is consistent with the forming surface, etc., which results in a large forming stroke of the mold structure condition and a small pressing area. In the initial mold design, the designer only considered the feature of small blanking surface, but ignored the guiding slide stroke of blanking core.