Is Metal Stamping Dangerous?

What is metal stamping? Hardware stamping is a process that uses punches and molds to deform or break stainless steel, iron, aluminum, copper and other plates and other materials to a certain shape and size.

Is metal stamping dangerous? I often see people asking such things in some metal stamping posts and forums. Why are there so many people asking about this or similar questions? Mainly because of the repeated occurrences of punching injuries, people have subconsciously believed that punching is a high-risk work, so is punching really that dangerous? Why do injuries often occur?

Metal stamping processing is dangerous, but it is not really that dangerous. As long as there is a stamping incident, there are reasons. On the one hand, it is the reason for the stamping plant, and on the other hand, it is the reason for the operation of the workers. As long as you do well in these two aspects, follow the stamping processing system, and operate properly, stamping is still very safe.

When a factory operates a punch press, how can it not be guaranteed that the punch press is fully qualified, and where does safety start? The main requirements for equipment are as follows:

1. The punch press works well

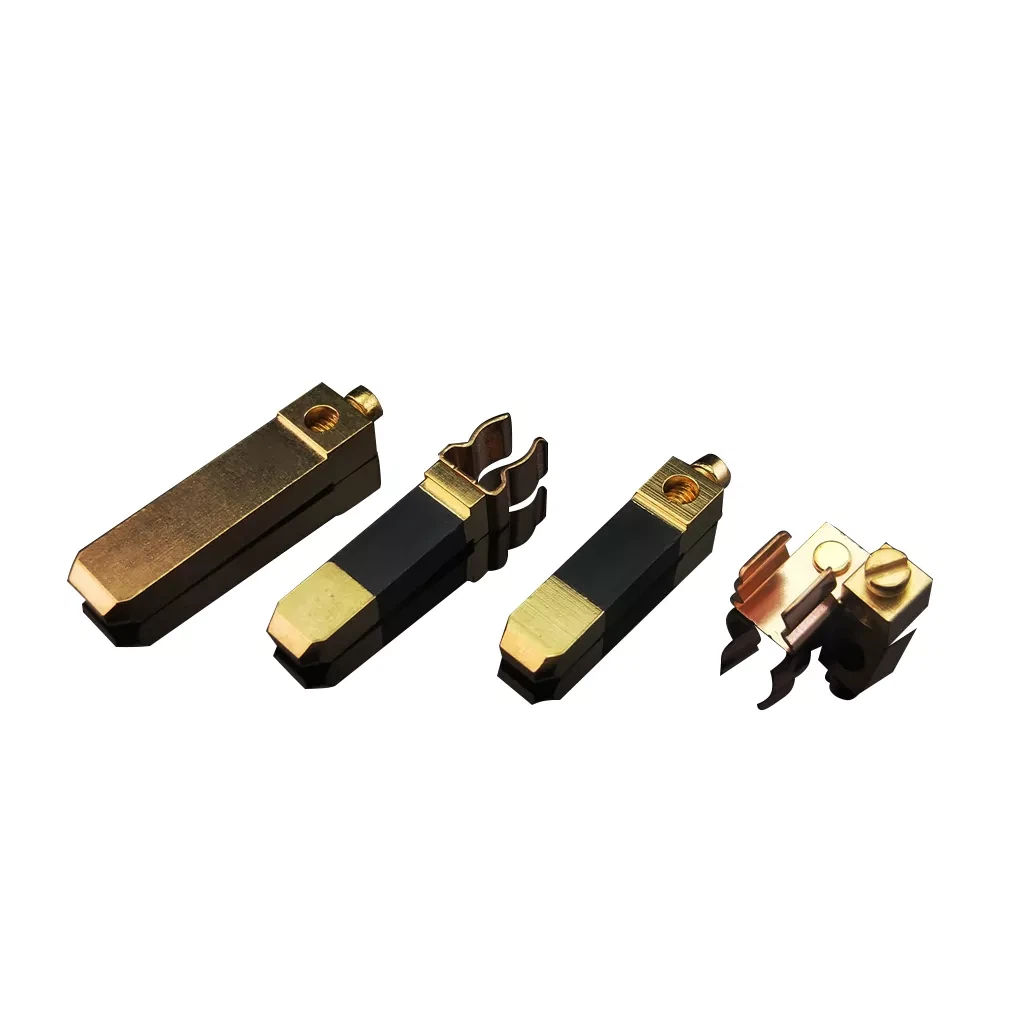

A good punch is the foundation of safe production. The lubrication of the punch must be normal; the copper bushes must not be excessively worn; the tightness of the brake must be within the normal range; the clutch and control system are flexible; the bolts of each part must not be loose;

2. Install safety grating

After the safety grating is installed, if the puncher's hands or other items that affect safety enter the dangerous area, the punch will be stopped in an emergency; in the shutdown state, the punch cannot be started. The picture below is a punch with safety grating

3. Reasonable switch design

It is necessary to design two start switches and an emergency stop switch, and the two start switches must be a certain distance apart. As long as the stamper presses the two start switches at the same time to start the machine; the emergency stop switch cannot be too far away from the stamper. Otherwise, when a situation arises, the worker cannot stop the punching machine for the first time.

4. Reasonable design of stamping die

If the punch is the first element of safe production, then the stamping die is the second element. The production of stamping parts relies on stamping dies, so whether the design of stamping dies is reasonable plays a vital role in safety. Whether it is convenient to discharge and return the material smoothly all affect the safety of the factory during operation. When designing the mold, it must be possible to ensure that the factory can easily use tools to unload and unload.

5. Safety tools must be used

During the stamping process, it is absolutely forbidden to let the hand enter the working area of the mold, which requires the use of safety tools to complete the work of unloading and unloading. The safety tools that are often used nowadays are magnet type, suction cup type and tweezers.

6. Establish a safety management system and punch operation manual

Stamping factories must carry out safety training for stamping workers from time to time, so that the concept of safe production can be deeply rooted in the hearts of the people. Help stampers to establish safe operating habits.