Design Points Of Transparent Panel Injection Mold

The transparent panel injection mold adopts PMMA plastic injection molding, PMMA has the characteristics of high light transmittance, but poor fluidity, and the injection molding process is difficult. Therefore, it is necessary to pay more attention to the transparent panel injection mold design and injection molding process. This article mainly introduces the design points of transparent panel injection mold.

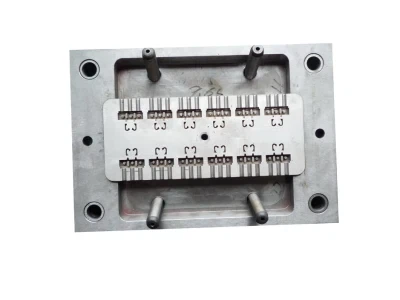

1. Determine the number of mold cavities according to the size and thickness of the product and the injection volume of the injection molding machine. The transparent panel is a balanced flow channel. Generally, one mold and two cavities are opened. When the size is small, four cavities can be opened. If more than 4 cavities are opened, the operation difficulty of the injection molding machine will be increased, resulting in an increase in the defect rate.

2. The selection of the parting surface, because the shape of the transparent panel is simple, the parting surface is generally selected along the edge of the plastic part to leave the movable mold of the plastic part. In addition, it is necessary to check the draft angle of the edge of the plastic part, the draft angle should be large enough, and whether there is a small R on the parting surface.

3. The selection of the glue feeding position of the transparent panel injection mold is very important. In the PMMA mold, the mold flow channel should be bent into an S shape, and the end of the flow channel is designed with a long cold material well, otherwise it is easy to produce air lines and melt glue during production. trace. The large end of the injection molded part selects the gate, so that the plastic can easily fill the cavity, and the glue line of the two holes is not obvious.

4. In the design of the exhaust position, generally the transparent panel is not allowed to have thimble marks, so it is necessary to open the auxiliary flow channel to help the ejection, and this flow channel also plays the role of exhaust.

5. The choice of steel used for transparent panel injection molds. Generally, the output is less than 100,000. Japanese NAK80 can be used. If the output is large, S136 or other steel with good grinding performance should be selected, heat treated to HRC48-52, and after finishing Polished, can get very good results.

6. The ejection design of the transparent panel mold. Generally, the transparent plate does not allow the appearance of thimble marks. The ejection of the plastic part is the ejector pin designed at the injection port. A thimble is ejected, and the plastic is released smoothly.

7. Cooling system design. The front and back molds of the transparent panel injection mold are designed with cooling systems to ensure that the process parameters can be well adjusted during injection molding.

8. The main channel of the transparent panel injection mold is facing the cold material well, and it must be designed with a Z-shaped pull rod, and the inverted pull material cannot be used.