Special Requirements Of Stamping Die For Stamping Parts.

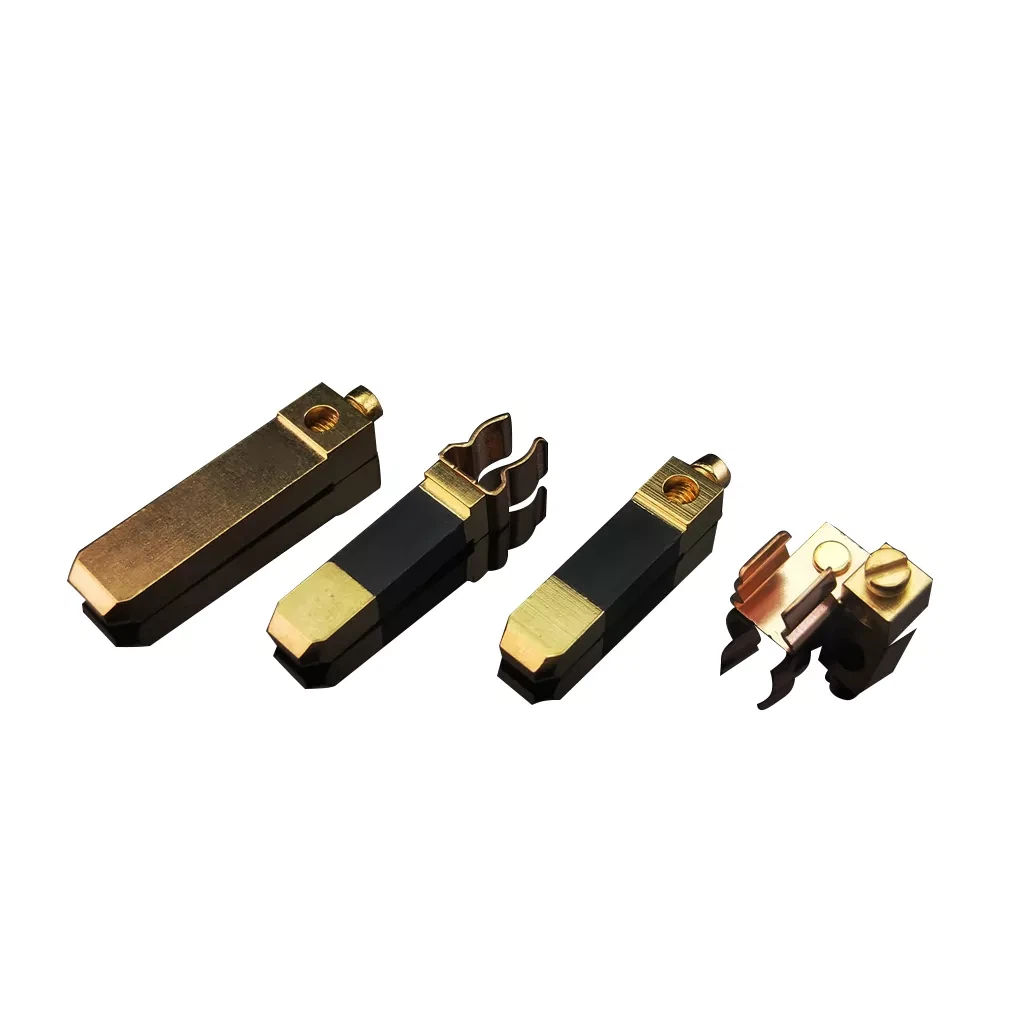

There are many stamping parts (switch socket and lampholder)in our prouducts

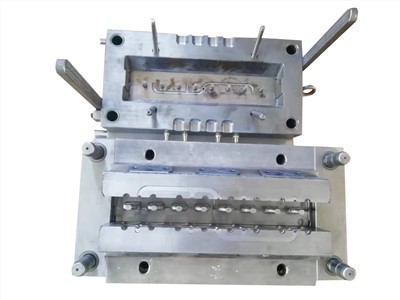

The automatic feeding device is installed on the metal stamping die to replace the manual feeding operation of the stamping worker. By using the continuous stamping of the ordinary punch, the high-speed automatic stamping die can be completed. We call it the automatic feeding stamping die. When using automatic feeding stamping die for automatic stamping, there are generally the following special requirements:

1. Steel must use small steel strips or long strips

For general stamping dies, most of us use small-sized materials with sheared plates, but if the automatic feeding stamping dies in high-speed stamping still use small-sized materials for stamping, then the raw materials need to be replaced frequently, so it is difficult to exert automatic stamping. of high efficiency. Therefore, the automatic feeding stamping die is suitable for the use of small coils or long strips (more than 10m). If the object to be sent is a semi-formed blank, in order to improve the stamping efficiency, it is necessary to arrange the parts before sending it.

2. There must be a precise positioning device inside the mold

Due to the limited accuracy of the feeding step of the feeding device attached to the mold, it can only reach ±0.05-±0.1mm at most. Therefore, a precise positioning device must be installed inside the mold to precisely position the feeding step of the feeding device to ensure that the accuracy of the feeding step meets the requirements.

3. The waste or workpiece produced by stamping must be able to be automatically discharged

In the continuous stamping state of the punch, it is impossible and impossible to use manual output. In order to ensure the timely discharge of waste materials or workpieces in the mold, an automatic discharge device must be installed. In addition, the die structure in the die should give priority to the use of a lower discharge die with automatic part ejection.

Automatic feeding stamping dies generally have the following special requirements

4. Stamping parts should be formed in the mold at one time as much as possible

After the automatic feeding device is attached to the stamping die, the manufacturing cost of the die will increase. If the single-process stamping scheme is still used, the stamping efficiency will be effectively improved. Therefore, the stamping parts should be formed at one time in a pair of automatic feeding stamping dies, so that the stamping speed is high, which helps to reduce the product cost.

5. The feeding distance should be kept stable