Solutions to stamping waste produced by metal stamping

1. The raw materials must meet the specified technical conditions (strictly check the specifications and grades of the raw materials, and conduct laboratory inspections on the workpieces with high dimensional accuracy and surface quality requirements under conditions.);

2. All links specified in the process regulations should be fully and strictly abided by;

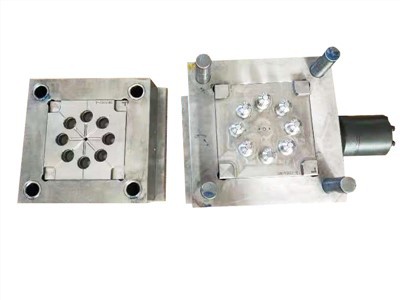

3. The presses and die and other tooling equipment used should be guaranteed to work under normal working conditions;

4. A strict inspection system has been established during the production process. The first stamping parts must be fully inspected and inspected.

It can be put into production only after it is qualified. At the same time, the inspection should be strengthened. When an accident occurs, it should be dealt with in time;

5. Adhere to the civilized production system, such as the transfer of workpieces and blanks, must use appropriate workstations, otherwise the surface of the workpiece will be crushed and scratched and the surface quality of the workpiece will be affected;

6. During the metal stamping process, the mold cavity should be kept clean, and the orderly processed workpieces should be arranged neatly in the workplace.