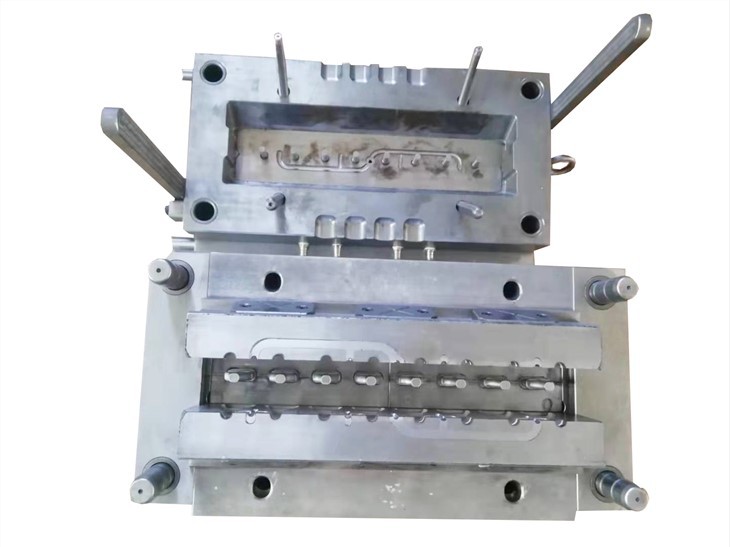

B22 Injection Mold

Mold Material: H13

Key point on quality of product: the design is as per customers requirement. If the engineer team is soft & not stronger. We will have product and waste material together. For the complete product, they can be fall down 100% due to weight cause.

Features

.

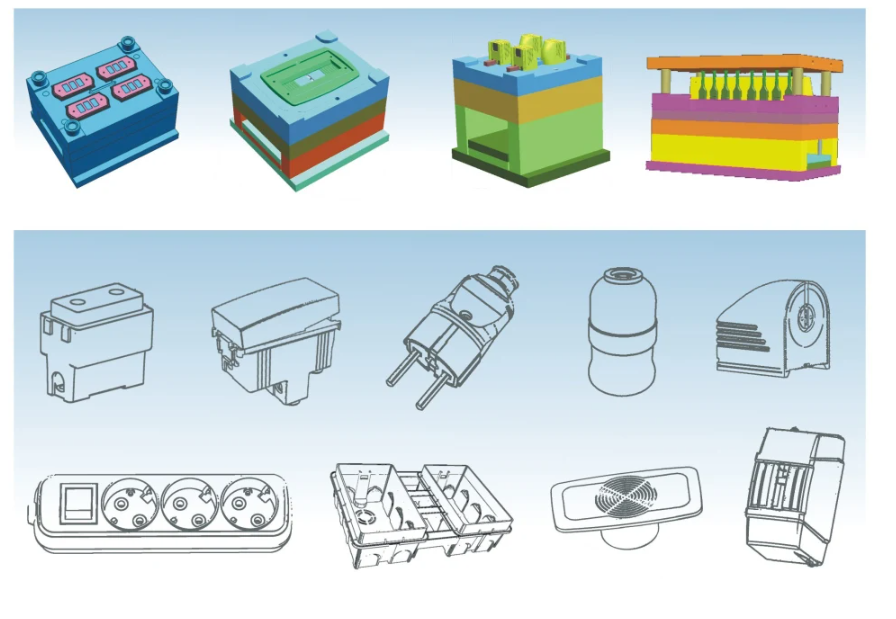

The B22 Injection Mold is a high-quality product designed for manufacturers who are seeking superior performance and reliability in their production lines. As a leading manufacturer in the industry, we understand that offering high-quality products is only part of the equation. Providing merchants with a comprehensive introduction to the product’s capabilities is just as important in ensuring that you make an informed decision when purchasing our product.

One of the key features of the B22 Injection Mold is its robust design and construction. Our engineers have taken painstaking measures to design a mold that is built to last, using the best materials and production techniques available. This means that the product is ideal for high-volume manufacturing applications, where consistency and quality are paramount.

The B22 Injection Mold is also incredibly versatile, and can be used with a wide range of materials. This includes not only standard plastics, but also more exotic materials such as fiberglass, composites and other high-strength polymers. This ability to work with a wide range of materials is particularly useful for manufacturers who produce products for specialized industries, such as aerospace, automotive and medical device manufacturing.

Another key advantage of the B22 Injection Mold is its ease of use. Unlike many competitor products, which require extensive setup and calibration, our mold can be quickly and easily configured to suit your manufacturing needs. This not only saves valuable time, but also reduces the need for costly retooling and downtime, which can have a significant impact on your bottom line.

In addition to these core features, the B22 Injection Mold incorporates a range of other advanced features that make it stand out from the crowd. For example, the mold is designed with computer-aided manufacturing (CAM) technology, which enables precise control over the manufacturing process. This means that you can achieve more accurate results, and produce products with a high degree of consistency.

The mold is also designed to be highly customizable, with a range of optional modules and components that can be added to suit your specific requirements. This includes features such as specialty sensors, custom heaters, and advanced cooling systems, which can all be tailored to your specific needs.

Given all of these benefits, it is clear that the B22 Injection Mold is an excellent choice for manufacturers who demand the very best in terms of performance, reliability and quality. Whether you are a small startup or a large-scale manufacturing operation, our product is sure to meet your needs and exceed your expectations.

So if you are looking for a high-quality injection mold that delivers superior results, look no further than the B22 Injection Mold. To learn more about this exciting product, please contact us today and speak to one of our experienced sales representatives. We are confident that once you try our product, you will never want to go back to anything else!

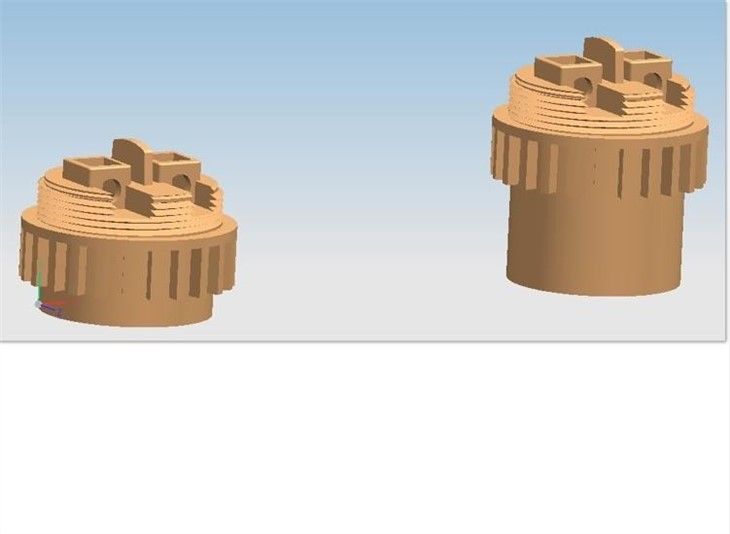

Short description: B22 holder with thread, side hole on product Mold Material: H13

Key point on quality of product: the design is as per customers requirement. If the engineer team is soft & not stronger. We will have product and waste material together. For the complete product, they can be fall down 100% due to weight cause.

Quality:

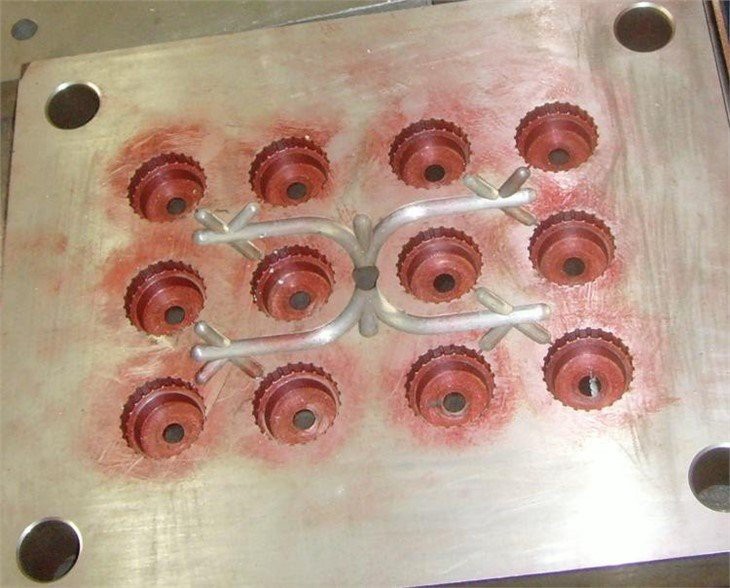

For the pin size, it must be controlled as per connector dimension. Also we keep the option for possible replacement. Due to product market position, some times it is in bigger connector like 5x5x8 brass connector, we should have bigger pin for finished product.

Design:

We combined the circle part to reduce the labor cost on assembling and injection cost on circle part ;

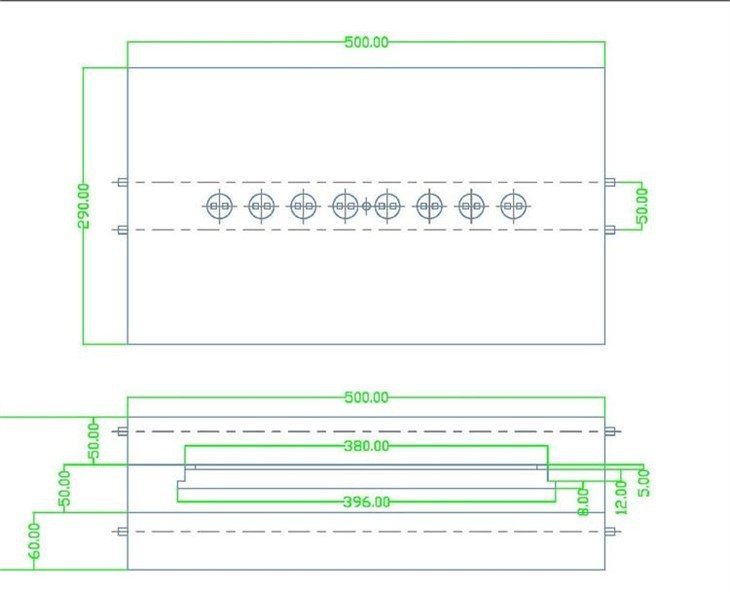

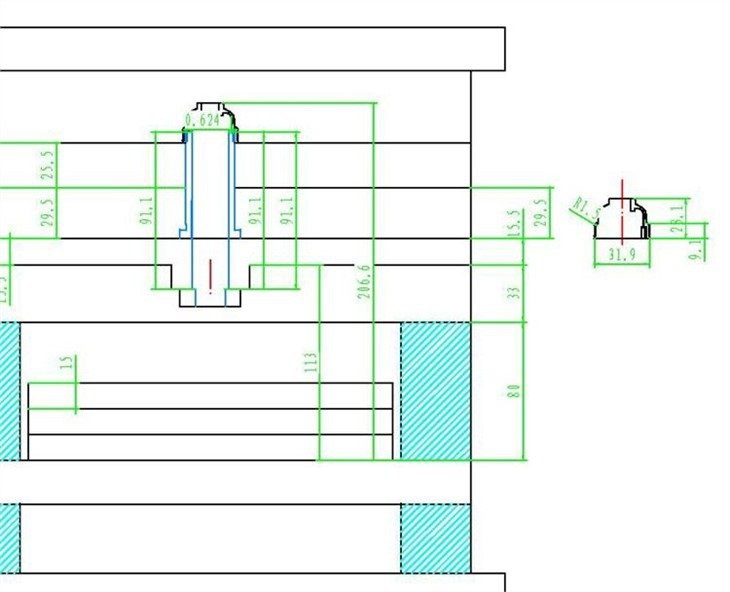

Mold details:

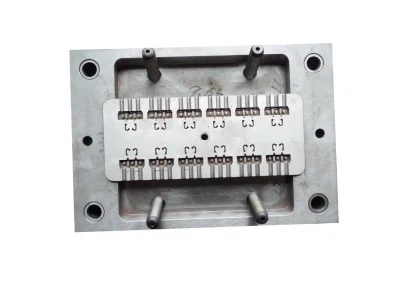

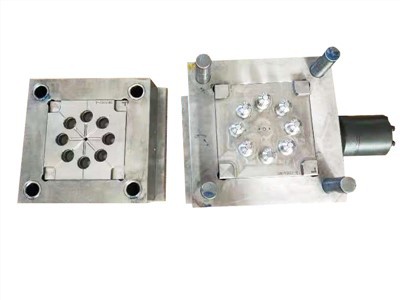

For the cavity number, it is 8 cavities. The mold become with more length. So we have extra pin for sliding part. Also we will have position on sliding

Mold spare part for possible use: pin and ejector

FAQ:

How many shot from mold design ?

Normally, it is design for 1 million shot. For this working life, it is from material character. In other word, the real running will come with difference. As if the mold receive well and professional maintenance. The mold life is more. If failed, the life time will be less.

Why the price comes big difference for same product ?

Generally, it is from material, finishing, design. Also experience. As mold is special, not from mass production. But we have to use the standard part from top brand company. LIKE DME, HASSCO, LKM. Also some key part should be finished from good machine.

Why choose us?

- Our products are designed and manufactured with utmost precision to ensure flawless results.

- Small business check out to our factory in Uganda can also be welcome at any time.

- Our commitment to excellence and attention to detail are evident in every Plastic Injection Moulding product we produce.

- At the same time, establishing a solid high-yield financial management mechanism.

- As a leading Plastic Injection Moulding manufacturer, we are constantly innovating to bring new and improved products to the market.

- We put our heart and soul into every detail, constantly improve the quality of our B22 Injection Mold and services, and pursue to bring the ultimate experience to our customers.

- We provide exceptional customer service to our clients who choose us as their Plastic Injection Moulding supplier.

- Warmly welcome to join us, let's innovation collectively, to flying dream.

- We offer customized Plastic Injection Moulding solutions that cater to both small and large scale manufacturing needs.

- Our company philosophy: to attract customers with technology; to satisfy customers with products; to move customers with service.

Hot Tags: b22 injection mold, China b22 injection mold suppliers, manufacturers, factory, Brass Plug Male Pin, Lampholder Connector, Wiring Device Injection Mold, Brass Electrical Component, B22 Injection Mold, Copper Stamping Parts

You Might Also Like

Send Inquiry