Lamp Holder Injection Mold

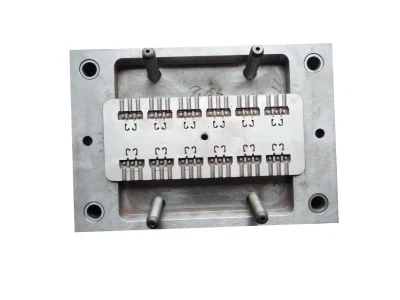

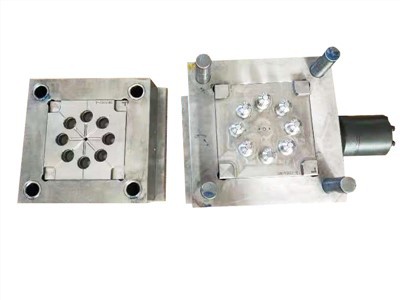

Mold Material: H13 HRC48-50 Cavity number: 8 cavity or 4 cavity if it comes with sliding

Key point on quality of product: thread size tolerance, full circle thread

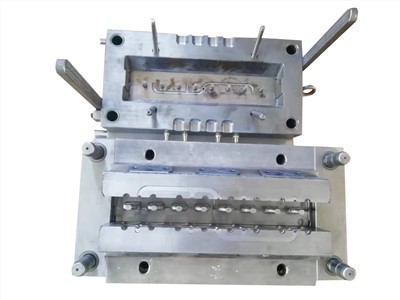

Short description: it is mainly for E27 and B22 model. They are from two part (cap and base)

Features

.

Introduction:

Welcome to our product introduction on our Lamp Holder Injection Mold. We are a Chinese manufacturer that specializes in producing high-quality molds for different types of products. Our lamp holder injection mold is one of our best products available in the market today. We take pride in producing high-quality molds that meet the specific needs of our clients.

In this product introduction, we will show you the specifications, features, benefits, and applications of our lamp holder injection mold. We aim to give you enough information to help you make an informed decision about choosing us as your supplier.

Specifications:

Our lamp holder injection mold is made of high-quality materials that ensure durability and longevity. The mold is made of high-quality steel and aluminum that allows for easy injection of plastic material. The mold is designed to meet the specific needs of our clients in terms of shape, size, and overall design. Here are the specifications of our lamp holder injection mold:

- Material: Steel and aluminum

- Mold cavity: Single/multiple

- Mold type: Hot runner or cold runner

- Surface Finish: Mirror polishing, sandblasting, or texture

- Tolerance: +/- 0.03mm

Features:

Our lamp holder injection mold has several unique features that set it apart from other molds available in the market. We have incorporated the latest technology in our mold production process that ensures superior quality and performance. Here are some of the features of our mold:

- Perfect injection: Our mold allows for precise and perfect injection of plastic material, which ensures quality and consistency of the final product.

- Durable and long-lasting: The high-quality construction materials of our mold ensure durability and longevity, which saves you time and money in the long run.

- Multiple cavities: Our mold can produce multiple cavities of the same product, which increases production efficiency and reduces production time.

- Easy to use: Our lamp holder injection mold is user-friendly, which means it is easy to operate and requires minimal maintenance.

Benefits:

Our lamp holder injection mold offers several benefits to our clients. We believe that our clients deserve the best products that offer value for money. Here are some of the benefits you can expect from our mold:

- High-quality products: Our mold produces high-quality and uniform products that meet the specific needs of our clients. This means you get products that are consistently of high quality, which improves customer satisfaction and loyalty.

- Increased production: Our mold can produce multiple cavities of the same product, which means you can produce more products in a shorter period, and this increases your production efficiency and profitability.

- Time and cost savings: Our lamp holder injection mold is durable, long-lasting, and requires minimal maintenance, which saves you time and money in the long run.

- Customization: Our mold can be customized to meet the specific needs of our clients, which means you can produce unique products that stand out in the market.

Applications:

Our lamp holder injection mold is designed to produce high-quality lamp holders that meet the specific needs of our clients. The mold can be customized to produce different shapes, sizes, and colors of lamp holders. Our lamp holder injection mold is ideal for the following applications:

- Residential lighting

- Commercial lighting

- Industrial lighting

- Automotive lighting

- Outdoor lighting

Conclusion:

Our lamp holder injection mold is one of our best products, and we take pride in producing high-quality molds that meet the specific needs of our clients. We have incorporated the latest technology in our mold production process to ensure superior quality and performance. If you are looking for a reliable and trustworthy supplier of lamp holder injection molds, you have come to the right place. We are committed to producing high-quality molds that offer value for money. Contact us today to get started.

Lamp holder injection Mold:

Mold Material: H13 HRC48-50 Cavity number: 8 cavity or 4 cavity if it comes with sliding

Key point on quality of product: thread size tolerance, full circle thread

Short description: it is mainly for E27 and B22 model. They are from two part (cap and base)

Quality:

Smooth running on thread part

Quality control:

Finishing all running part by good polishing machines

Mold details:

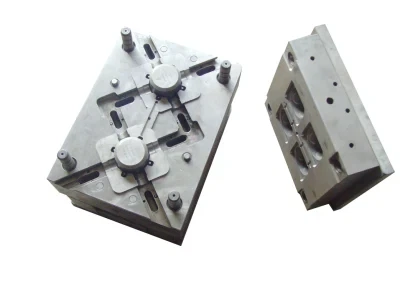

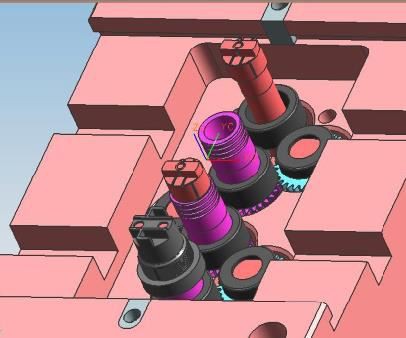

The mold design is via oil hydraulic motor. For the gear size, it is well organized. Also for each gear, it should be with corner cutting to avoid possible flash during gear touching.

Mold structure:

Injection machines size: 1200kn or bigger Injection material: PA

For running speed, it is controlled as per design.

Mold spare part for possible use: normal running part like core part

If it comes with sliding, we should have more care on gear position. And improve the grade of bearing. For bearing brand like skf or similar Germany brand.

Mold finishing and packaging:

For thread mold, we will have full core part finished from one machines. In this case, the size tolerance will be controlled. Also the finishing of thread, they are 100% as per drawing. In this case, the product will be ensured good and fast assembling. As we reduce the thread, it is good for reduce motor time and 100% product off. But when cap work with base, they must match closely.

If the material of thread part, like cap in different material, we have to add more thread. It will increase the assembling time. But for end user, it is good for product fixing.

Why choose us?

- As a leading Plastic Injection Moulding manufacturer, we are constantly innovating to bring new and improved products to the market.

- We comply with the requirements of sustainable development strategy in our business activities and pay attention to ecological and environmental protection.

- Our commitment to excellence and attention to detail are evident in every Plastic Injection Moulding product we produce.

- The company's tenet of providing users with full-process and all-round services enables you to have a more assured service while owning a good product. From selection to after-sales, we can provide you with a one-stop solution for Lamp Holder Injection Mold.

- As a leading supplier and manufacturer, we are committed to providing our customers with the best possible prices.

- We use quality and credibility to open up the market, rich varieties to meet customer needs, and continuous reform to improve customer satisfaction.

- Our Plastic Injection Moulding products are rigorously tested to ensure their safety, durability, and long life.

- We always maintain an understanding of the latest research trends in [Lamp Holder Injection Mold field.

- Our Plastic Injection Moulding products are suitable for various applications, including automotive, medical, and aerospace industries.

- To cultivate talents means to do a real good job of guidance, design and management, and to continuously strengthen the training of talents.

Hot Tags: lamp holder injection mold, China lamp holder injection mold suppliers, manufacturers, factory, Brass PCB Terminal Connectors, B22 Injection Mold, E27 Injection Mold, socket brass stamping part, Electric Pin For Plug, Precision Brass Part

You Might Also Like

Send Inquiry