How To Improve The Quality Of Metal Stamping Parts To A Higher Level

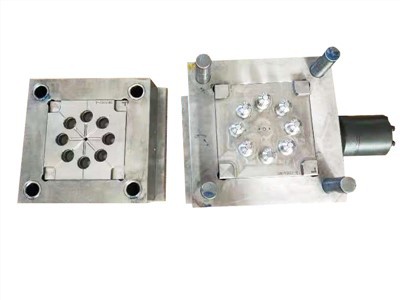

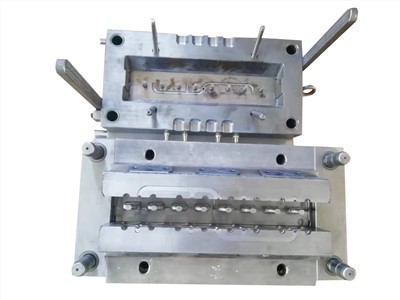

1. Adjust the appropriate gap between the concave and convex molds to avoid scratching the surface of the workpiece when the gap is too small or uneven.

2. Keep the surface of the concave-convex mold clean. The blank of the metal stamping parts needs to be wiped clean before stretching to avoid the working surface of the mold or the surface of the material from being dirty and inclusions, which will damage the surface of the metal stamping parts and affect the surface quality of the mold.

3. Appropriately increase the surface hardness of the punch and die, and check the surface of the punch and die during the stretching process, even if the residual metal shavings are removed, because when the hardness of the punch and die is low, the metal shavings adhere to On the surface, this will also cause pull marks on metal stamping parts.

4. Polish the corner radius of the mold to avoid the rough surface of the mold corners and scratches on the surface of the metal stamping parts during stretching.

5. Use lubricants suitable for deep drawing process. If necessary, filter the lubricant before use to prevent impurities from entering. If the lubricant is of poor quality, the surface roughness of the stretched metal stamping parts will increase, thereby reducing stamping accuracy and quality.