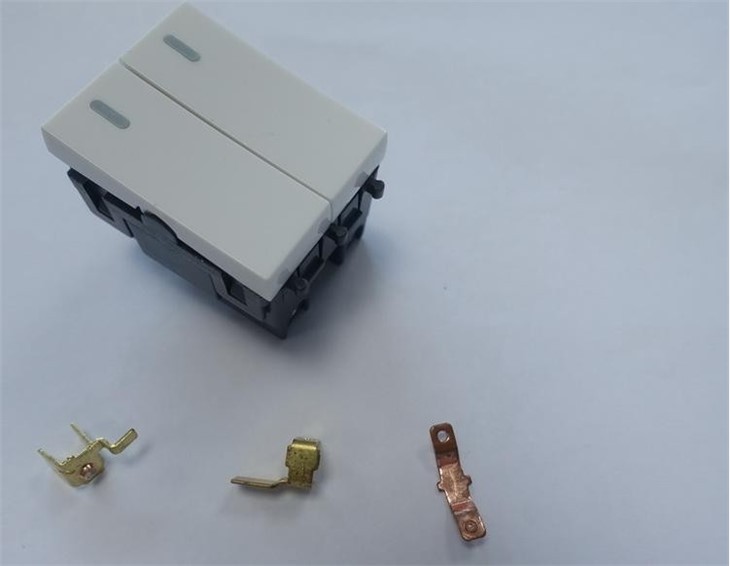

Brass Stamping Part

Key point on quality: Material and finishing, The brass stamping part can be suitable for automatic assembling.

Specification: thickness in 1.0mm, 0.8mm Material in brass;

Features

Introduction:

Hello and welcome! In this product introduction, we will be discussing our Brass Stamping Part which is manufactured in China and available for wholesale to merchants all over the world. This product has been designed for a wide range of applications in various industries, including automotive, electronics, construction, and many more. Our brass stamping parts are known for their durability, reliability, and excellent quality.

Material and Manufacturing:

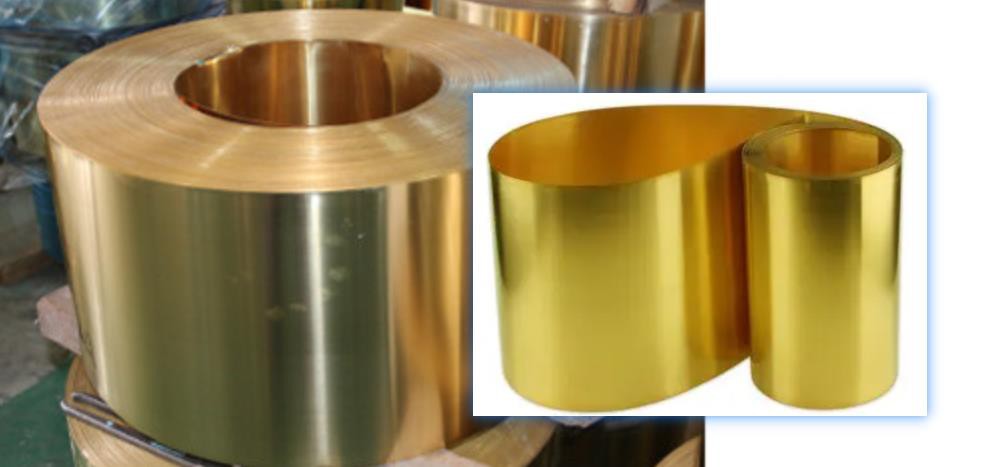

Our Brass Stamping Part is made of high-quality brass material that ensures maximum protection against corrosion, wear, and tear. The material is carefully selected to meet specific requirements and undergoes rigorous inspection before production. We use advanced manufacturing techniques, including stamping and precision machining, to produce parts that meet or exceed international standards.

Design and Features:

Our Brass Stamping Parts are versatile and come in a range of sizes and shapes. They can be customized to meet your specific requirements, including thickness, diameter, and length. The design of the part ensures easy installation and a perfect fit in various applications. Additionally, our brass stamping parts can withstand high temperatures, pressures, and other challenging conditions, making them ideal for use in demanding environments.

Applications:

Our Brass Stamping Parts are suitable for a wide range of applications, including electrical, automotive, aerospace, and construction industries. Due to their excellent conductivity, they are ideal for use in electrical connectors, switches, terminals, and various other applications where conductivity is critical. Additionally, the high strength and durability of our brass stamping parts make them perfect for use in demanding environments such as the automotive industry, where they are used in the manufacturing of engines, transmissions, and other components.

Quality Control:

At our factory, quality control is a top priority, and each part is carefully inspected at every stage of the manufacturing process to ensure it meets our high standards. We pride ourselves on producing parts that are not only high quality but also cost-effective. Our state-of-the-art testing facilities ensure that our brass stamping parts undergo meticulous testing to meet or exceed industry standards.

Why Choose Our Brass Stamping Parts?

We manufacture our Brass Stamping Parts using the most advanced techniques and highest quality raw materials. Our parts are durable, reliable, and provide outstanding performance in demanding applications. Additionally, we offer competitive pricing, fast delivery, and world-class customer service to ensure that our clients are fully satisfied.

Conclusion:

In conclusion, our Brass Stamping Part is a high-quality product that offers excellent performance and durability. It can be used in a wide range of applications across various industries, and we offer customization to meet specific requirements. We stand behind our products and offer competitive pricing, fast delivery, and exceptional customer service. Contact us today to learn more or place an order. Thank you!

Key point on quality: Material and finishing. Specification: thickness in 1.0mm, 0.8mm Material in brass;

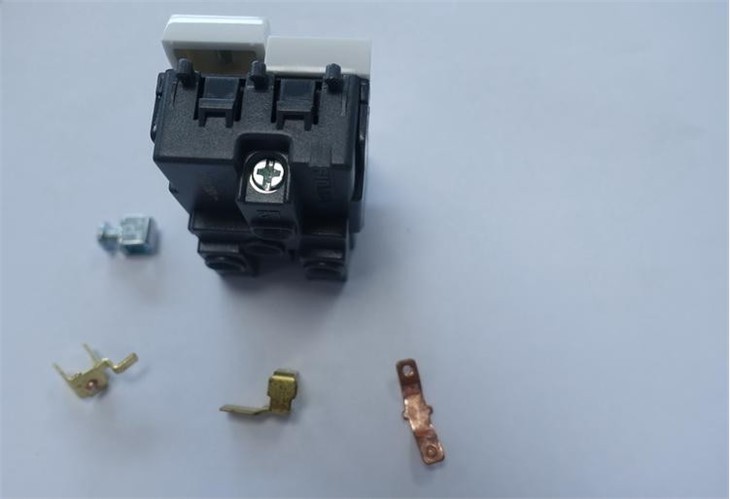

Application:

For switch, mainly use 1 gang 1 way, 1 gang 2 way, 2 gang 1 way, 2 gang 2 way, 3 gang 1 way, 3gang 2 way.

Surface finishing:

Normal it is yellow color, some required part in plating silver. The thickenss of silver will be made as per drawing & market requirement or testing standard.

The hardness on material:

Middle level, and the moving contact is key for complete product working. So the brass part size should be controlled within 0.02-0.01mm.

For terminal connector:

The above item in iron plated nickel material. If there is higher requirement, it can be brass material. Also we can change the complete terminal part in brass connector finishing from turning machine. It will help temperature rise a little.

Tooling for brass stamping part:

We have own design and full automatic running. The speed is controlled 80pcs per minute. For some item less angle, the speed can be more.

Raw material status:

Why choose us?

- We offer a wide range of metal stamping products that are customizable to meet the needs of diverse industries.

- We actively promote the construction and management of technological innovation platform, and continuously improve the investment mechanism of technological innovation.

- Our metal stamping products are designed to provide maximum performance and durability, while also offering aesthetic appeal.

- We adhere to the system innovation and product structure optimization, combined with international innovation technology, and spare no effort in the R & D and manufacturing of high-quality Brass Stamping Part.

- Our metal stamping products are designed to withstand extreme conditions and are built to last.

- We have been occupying the market with unique professional knowledge, excellent product quality, and complete supporting services.

- Our team carefully listens and analyzes clients' requirements to determine the metal stamping product that meets their specific needs.

- Our mission is to provide state-of-the-art Brass Stamping Part to our customers worldwide, providing a solid customer base for our company's globalization strategy.

- We embrace sustainable and environmental-friendly manufacturing practices in our metal stamping product production.

- We are searching ahead towards your visit for Brass Stamping Part.

Hot Tags: brass stamping part, China brass stamping part suppliers, manufacturers, factory, socket metal stamping part, Brass Electrical Component, Brass Plug Pin, B22 Injection Mold, Wiring Device Injection Mold, Brass Neutral Links

You Might Also Like

Send Inquiry