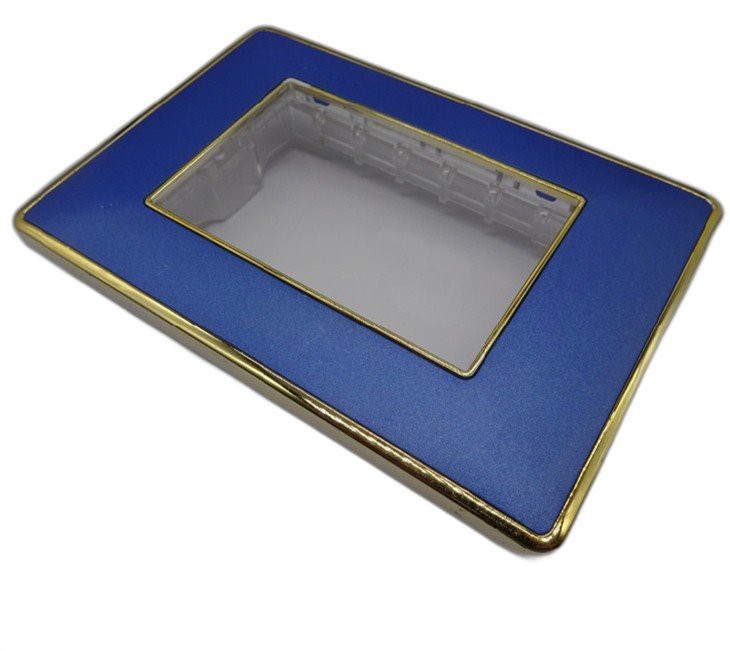

Wiring Device Metal Part

Material: brass, copper, iron

Key point on quality: improved design as per plastic body & finishing of size & shape

Short description: they are mainly finished via progressive die. But bar part to MCB, they are from shaping machines. the thickness is from 0.8 to 1.5mm.

Features

.

Products that ensure the functionality, durability, and safety of buildings and appliances are essential to the modern marketplace. In that light, Wiring Device Metal Parts have long been a staple of the construction industry. As a manufacturer located in China, I am proud to introduce our latest offering in that domain. Our Wiring Device Metal Part is a carefully crafted product that stands out in every possible aspect. The following article will highlight the many unique features of our product.

The Wiring Device Metal Part is a versatile and innovative product that caters to the unique demands of the modern construction industry. Our product enables flawless connections between wires and electrical devices, ensuring that they remain in place and functional throughout their lifespan. Our Wiring Device Metal Part is made of high-grade materials, including brass, copper, and aluminum. These materials are carefully selected for their high strength, corrosion resistance, and longevity, making them a perfect match for the quality-demanding construction industry.

At our manufacturing facility, we take pride in our craftsmanship and diligently work towards delivering the best quality products to our customers. Our Wiring Device Metal Part is manufactured using state-of-the-art technology, which allows us to maintain consistency and precision throughout the production process. Our automated equipment ensures that every detail of the product is perfect, which contributes to its superior quality.

The Wiring Device Metal Part comes with a range of features that make it the perfect solution for modern construction demands. Our part is designed to ensure ease of installation and versatility in meeting the requirements of different applications. Our product is durable and highly resilient, making it suitable for use in extreme environmental conditions. Additionally, our product is highly conductive, making it easy to conduct power effectively.

We understand that safety is a top concern for all construction projects, which is why we have taken every step to ensure that our Wiring Device Metal Part meets the highest safety standards. Our product is thoroughly tested and verified to ensure it's safe for use in construction applications. From the moment of manufacturing to deployment on-site, our products are subject to intense scrutiny to ensure every detail meets the desired safety standards.

Another key feature of our Wiring Device Metal Part is its ability to withstand high levels of stress and strain. Our product is designed to withstand mechanical, thermal, and electrical stress, which are common in various construction applications. Not only is our product highly resistant to negative forces, but it is designed to provide maximum potency, making it highly reliable for different applications.

One significant advantage of our Wiring Device Metal Part is its commitment to sustainability. Our Wiring Device Metal Part is manufactured using environmentally sustainable materials, such as recyclable metals. We realize that sustainability is critical to the modern marketplace, and we are committed to playing our part in ensuring an eco-friendly approach to manufacturing.

In conclusion, our Wiring Device Metal Part is a unique and innovative product that stands out in the construction industry. It's versatile, durable, and highly resilient, making it suitable for use in extreme environmental conditions. Our product is also highly conductive, ensuring efficient power transmission. Additionally, our product is highly resistant to mechanical, thermal, and electrical stress, which makes it highly reliable. Our Wiring Device Metal Part is committed to safety, and we have taken every step to ensure that our product meets the highest safety standards. We also take pride in our commitment to sustainability, making sure that our products are made using environmentally friendly materials. We are confident that our Wiring Device Metal Part will be a perfect choice for all construction needs, and we look forward to being your preferred supplier in that domain.

Product name:Wiring Device Metal Part Material: brass, copper, iron

Key point on quality: improved design as per plastic body & finishing of size & shape

Short description: they are mainly finished via progressive die. But bar part to MCB, they are from shaping machines. the thickness is from 0.8 to 1.5mm.

Application & finishing:

Junction box, wiring device, for matching part to MCB, they are fixed by screw, some design is finished by welding and metal with painting

Quality:

The size should be controlled as per drawing. As they are also for matching other part. Like MCB, Breakers. These product is in standard size.

Also there is another key point for thread. Like D.B box, it will be fixed by plastic cover with base via the above metal bar. If the thread is not good, the complete value one will not work.

For normal junction box, like AVE, Bticino part, the iron fixing part on plastic body is strengthened. For the thread and thickness, they are key factor. It can stand rough assembling. The improved design is not only metal part, some time, the plastic part is improved together. Easy installation, quick for people. And it can use for 20 times or more.

Delivery time: 35days

FAQ:

For Wiring device metal part, do you make some design for me as per our plastic body ?

Yes, we can have the service for this model business.

About junction box 10 x 15, 3 module, can you have lower price for this wiring box metal part ?

Yes, we can do it. as we have big production for them. Normally for this daily item, we have MOQ in 1 millions piece.

Why choose us?

- Our team has vast experience in designing and manufacturing metal stamping products for a variety of applications.

- We are a professional company for the production of Wiring Device Metal Part with complete and scientific quality management system.

- Our main goal is to provide our clients with metal stamping products that exceed their expectations.

- Our talent concept is to make the best use of people and talents, to provide a guarantee for the rapid growth and efficient operation of our company.

- Our metal stamping products are backed by extensive testing and quality control measures to ensure utmost performance and satisfaction.

- Technological progress has promoted the vitality and prosperity of the industry, which can stimulate more talents and creativity.

- Our metal stamping products are rigorously tested to ensure that they meet the highest quality standards.

- We are willing to cooperate with you, devote ourselves to the development and application of Wiring Device Metal Part, and establish long-term technical cooperation and business contacts.

- Our metal stamping products are tested and certified to perform under the most challenging conditions.

- Our company develops, manufactures, and sells advanced Wiring Device Metal Part for a broad range of customers around the world. Our quality service allows us to obtain trust and loyalty with our customers.

Hot Tags: wiring device metal part, China wiring device metal part suppliers, manufacturers, factory, Brass Plug Pins Flat, Lampholder Pin, Precise Plastic Parts For Machines, Lamp Holder Injection Mold, Brass Plug Pin, B22 Injection Mold

You Might Also Like

Send Inquiry