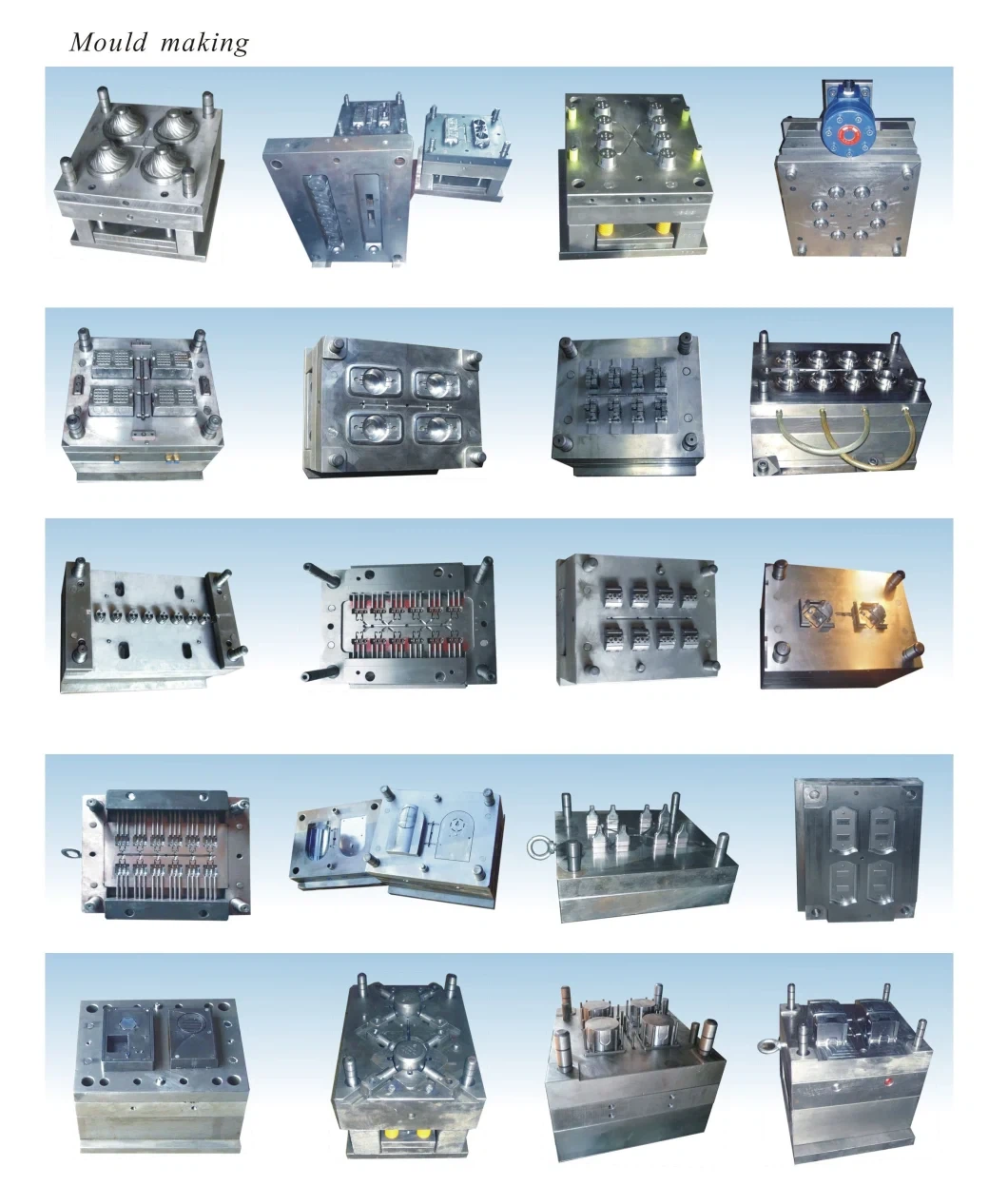

Socket Injection Mold

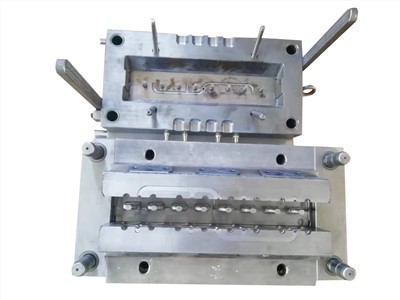

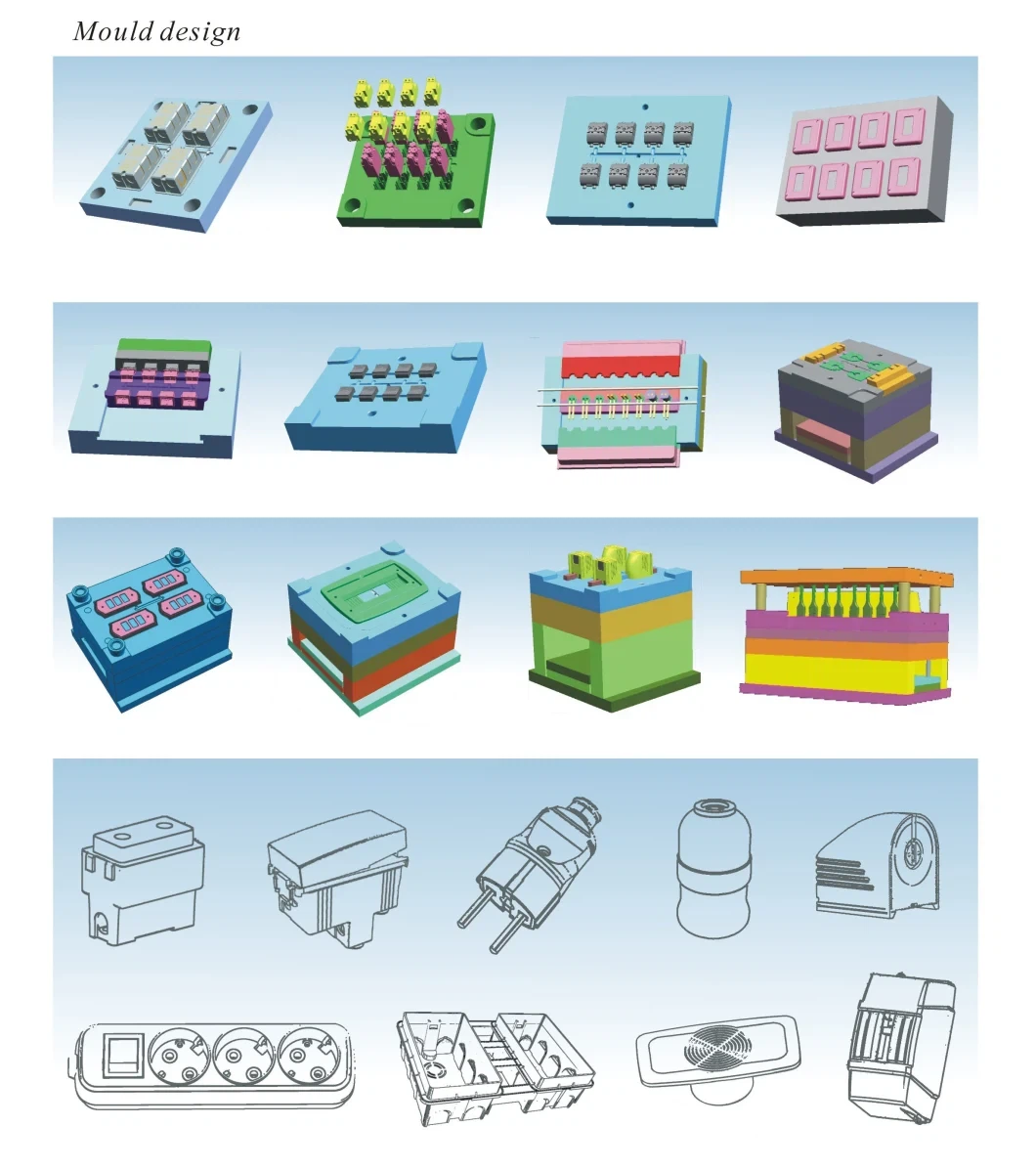

Ours plastic precise injection mold and tooling main production on Lampholder / Switch Socket / Plug / Box / MCB / Auto Connector / Distribution box

Our tool shop is able to produce instrumentation and special tools strictly based on the design and with the highest quality requirements, due to the experience of our specialists and the skilful use of new technologies.

Features

Introduction:

As a Chinese manufacturer, we are pleased to offer our high-quality Socket Injection Mold to merchants worldwide. Our product is designed to meet the growing demand for precision molding equipment in various industries, including automotive, home appliances, medical devices, and electronics. We have invested a considerable amount of resources in developing and testing our Socket Injection Mold to ensure it meets international standards and delivers optimal performance.

Key Features:

1. High Precision - Our Socket Injection Mold is engineered with advanced technology, using state-of-the-art machines to achieve the highest level of accuracy in molding. Our molds are fabricated with tight tolerances to ensure consistent and predictable results.

2. Durable & Long-lasting - We use high-quality materials to create our molds, ensuring that they are long-lasting and durable. Our molds are designed to withstand the rigors of industrial applications, making them a smart investment over time.

3. Customizable - Our Socket Injection Mold is designed to be customizable, accommodating a variety of sizes, shapes, and materials. This flexibility allows us to cater to the specific needs of our customers, delivering a product that meets their requirements.

4. Efficient - Our Socket Injection Mold is engineered with efficiency in mind. The molds are designed to minimize waste and increase productivity, providing a cost-effective solution to production needs.

5. Eco-Friendly - We are committed to maintaining environmental sustainability, and our Socket Injection Mold is designed to minimize waste and reduce the environmental impact of our activities.

Benefits:

1. Improved Product Quality - Our Socket Injection Mold offers precision molding, resulting in improved product quality, reduced waste, and increased efficiency.

2. Time and Cost Savings - Our Socket Injection Mold is cost-effective, reducing the production time required to produce quality products. Our product is also customizable, reducing the need for additional molds, which can save time and cost.

3. Competitive Advantage - Our Socket Injection Mold is a high-quality product that offers a significant competitive advantage to merchants looking to produce high-quality products efficiently.

Conclusion:

Our Socket Injection Mold is designed to meet the demands of a growing and competitive marketplace. Offering a range of benefits, including high-quality molding, cost and time savings, and a competitive advantage, our product is a smart investment for merchants worldwide. Whether you're in the automotive industry, producing home appliances, medical devices, or electronics, our Socket Injection Mold provides the flexibility, quality, and efficiency you need to succeed. Contact us today to learn more.

Mold Material:

S136, H13

Key point on quality:

size control, spare parts finished grade, design and matching status ;

Short description: the part matching go smoothly. Like sliding part, it can be pushed by Children finger

Quality:

Stability and working life , easy maintainance

Quality control:

All parts are from designed material. Also the size is finished 100% as per drawing

For complete assembling of mold, it should be finished little by little, not rough handling.

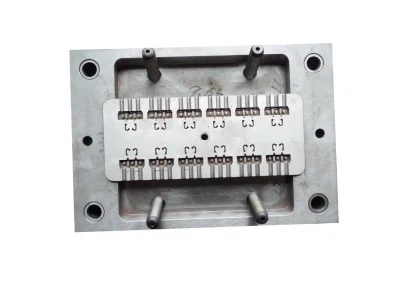

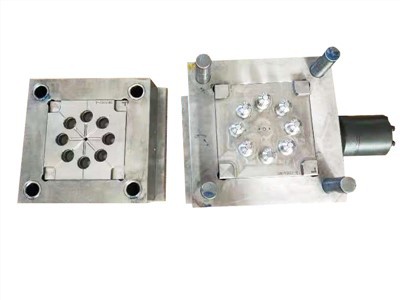

Mold details:

Switch bracket mold in 8 cavity, the mold is design for cold runner, the injection material is PC. About 25 second for one complete cycle injection time.

Key point for finish, the injection point should be small and the mold design is for fully automatic running.

Mold structure:

Normal up and down mold, no sliding via new improvement on product design.

Injection machines size:

1200KN. As this product is for inside matching part for switch. So we have the surface in matt status, not polished one for less cost.

There is no need to support from robot for this item. We just have waste material and product itself, off separately.

Mold spare part for possible use:

Ejector in normal size

Socket Injection molds are used to produce plastic parts through the injection molding process. They consist of several features that are crucial to ensuring the successful production of high-quality plastic parts.

We propose and manufacture a series of production equipment such as "material supply → material inspection → molding → product inspection → NG cut → product storage".

We have many experiences such as connectors, camera modules, precision motors, relays and contacts.Units can be organized according to customer requirements.

Why choose us?

- We provide exceptional customer service to our clients who choose us as their Plastic Injection Moulding supplier.

- We will cooperate with you wholeheartedly with excellent quality, low price and perfect service.

- We use advanced production techniques to ensure that our Plastic Injection Moulding products are of the highest quality.

- Our company stands out among many enterprises and becomes a pioneer in the Socket Injection Mold industry. Strong technical support, perfect after-sales service, and a complete management system enable each of our products to be recognized and praised by customers. We welcome new and old customers to cooperate with us.

- Our Plastic Injection Moulding products are designed to meet the unique needs and specifications of our clients in different industries.

- Our company adheres to the company culture of integrity, brand, quality and the future. We adhere to the business tenet of customer first and integrity-based, and put product quality and service in the first place.

- Our talented team of professionals is dedicated to providing the best Plastic Injection Moulding products and services in the industry.

- Our company has professional design ability, relying on advanced manufacturing and processing equipment, perfect quality control system, to produce efficient and durable products, to create value for customers with professional product quality.

- We are a Chinese factory that specializes in producing high-quality Plastic Injection Moulding products.

- Socket Injection Mold have advanced technical support and we can be invincible in the fierce market competition because of our company's perfect quality management system and after-sales service system.

Hot Tags: socket injection mold, China socket injection mold suppliers, manufacturers, factory, Brass Crimping Pin, Precision Brass Part, Brass Electrical Pins, Brass Plug Pin Flat, switch contact, Brass Electrical Component

You Might Also Like

Send Inquiry