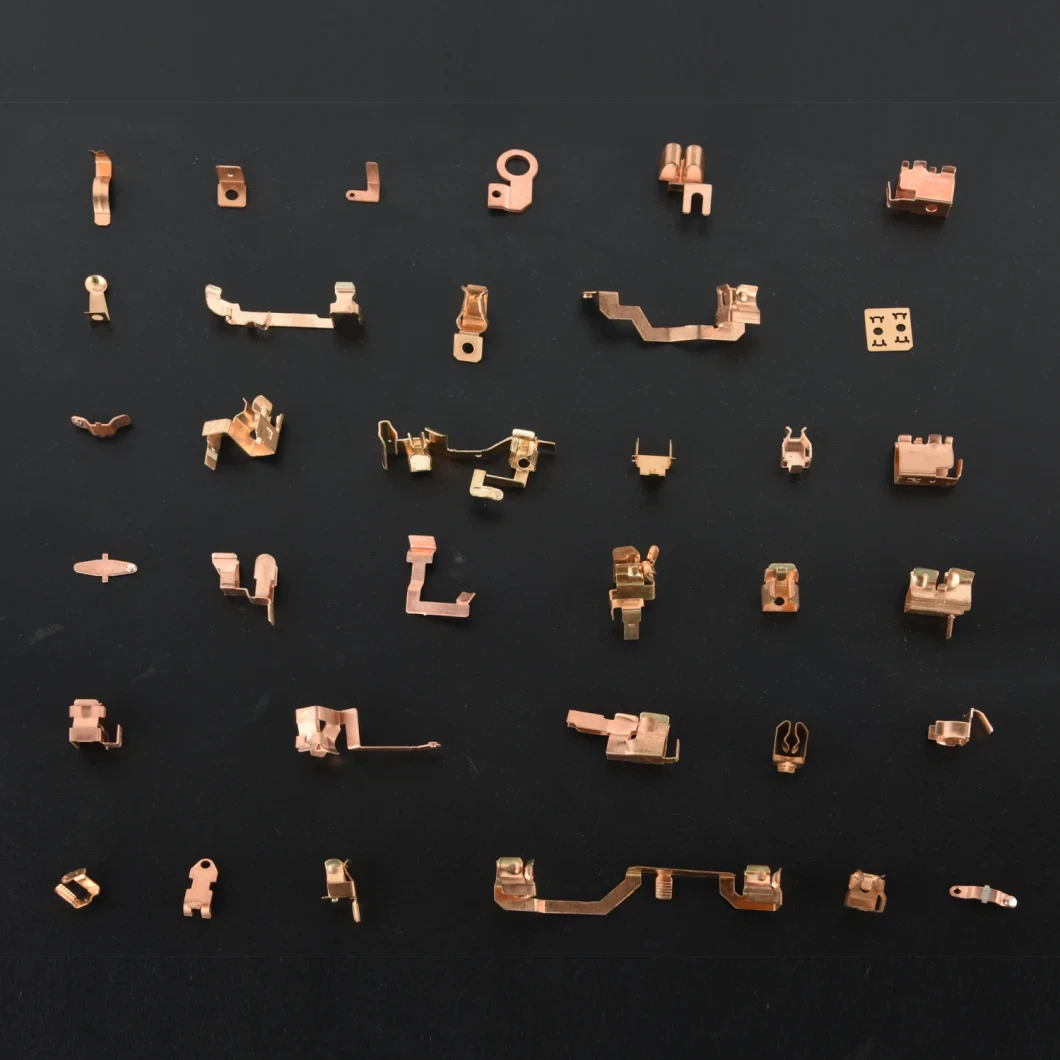

Socket Electrical Stamping parts

There are mainly three kinds of Electrical Contact Component :

1,Riveting Parts : contact is riveted on copper component

2,Welding Parts : sheet contact is welded on copper component

3,Stamping Parts: precious clad metal is stamped into contact bridge component

Our main include Electrical Contact Component, Plastic injection mold,Tailor-made spare parts for machine,Electrical products such as switch, socket, lampholder, plug, bell, etc;SKD, component & metal parts for electrical products.Plastic parts making & finishing

Features

Introduction:

As a manufacturer, we at [company name] are committed to providing high-quality electrical stamping parts that meet the needs of our clients. Our Socket Electrical Stamping Parts are an excellent choice for merchants looking for reliable and durable products to meet their electrical needs. These parts are designed to meet international standards, and our manufacturing process is in line with quality control guidelines, ensuring that you receive the best possible product.

Features:

What sets our Socket Electrical Stamping Parts apart from other products in the market? Here are some of the features that make them an excellent choice:

1. High-quality materials: Our Socket Electrical Stamping Parts are made using high-quality materials that meet international standards. This ensures that the parts are durable, reliable and can withstand harsh working conditions.

2. Precision manufacturing: Our manufacturing process involves precision stamping, which ensures that each part is of a consistent quality. This, in turn, helps to minimize the risk of defects or malfunctions, ensuring that your clients can rely on the products.

3. Customization options: At [company name], we understand that different clients have different needs. To ensure that we meet the needs of our clients, we offer customization options that allow you to tailor the Socket Electrical Stamping Parts to your specific requirements.

4. Wide range of applications: Our Socket Electrical Stamping Parts are suitable for a wide range of applications, from home electrical projects to commercial and industrial usage. This makes them an excellent choice for merchants looking to expand their product range.

Benefits:

The benefits of using our Socket Electrical Stamping Parts are manifold. Here are a few of the most significant benefits that your customers can enjoy:

1. Increased reliability: By using high-quality materials and precision manufacturing, we ensure that our Socket Electrical Stamping Parts are reliable and durable. This can help to reduce downtime and maintenance costs for your customers.

2. Customizable: With our customization options, your customers can create a product that meets their specific needs. This can help to increase customer satisfaction and loyalty, helping to grow your business.

3. Versatile: Our Socket Electrical Stamping Parts can be used in a range of applications. This versatility can help you to attract a broader range of customers.

4. Competitive pricing: By manufacturing our products in China, we can offer competitive pricing without compromising on quality. This can help your business to increase profitability and attract cost-conscious clients.

Conclusion:

At [company name], we are committed to providing high-quality Socket Electrical Stamping Parts to merchants outside of China. With our precision manufacturing, high-quality materials and customization options, we are confident that our product will meet the needs of your clients. If you are looking to expand your product range or provide your customers with a reliable and versatile product, our Socket Electrical Stamping Parts are an excellent choice.

Socket electrical stamping parts refer to the small metal pieces used in electrical sockets to connect to the wiring. These parts are usually made of high-quality metal, such as copper, brass, or bronze, and are shaped using a metal stamping process.

The electrical stamping process allows for the precise shaping and sizing of the parts, ensuring that they fit perfectly into the socket and provide a secure connection for electrical currents to flow through.

Socket electrical stamping parts may include clips, connectors, terminals, and other small metal pieces that are essential to the proper functioning of electrical sockets. These parts are typically used in a variety of applications including automotive, industrial, and consumer electronics industries.

Socket electrical stamping parts are precision metal components used in electrical socket applications. These parts are typically made from high-quality metals such as copper, brass, or stainless steel to ensure durability and long-lasting performance.

Some key features of socket electrical stamping parts are:

1. High precision: These parts are manufactured with high precision to ensure that they fit perfectly into the socket and provide reliable electrical connections.

2. Durability: Socket electrical stamping parts are made from high-quality metals that are resistant to corrosion and wear, ensuring long-lasting performance.

3. Customizable: These parts can be designed and manufactured with specific dimensions and shapes to meet the unique requirements of various electrical socket applications.

4. Easy installation: Socket electrical stamping parts are designed for easy installation, making it easy to replace them when necessary.

5. Cost-effective: These parts are cost-effective, making them ideal for mass production of electrical socket components.

Overall, socket electrical stamping parts are essential components in electrical socket applications that require reliable, high-quality, and durable parts.

Application:

It is key part for socket, and moving part for switch.

Quality control:

1) Working size and working area of this part ;

2) From mass production, it should be controlled by jigs, also it can be controlled by scanner if the size is controlled in 0.02mm;

If the product design is complete, we will follow all details as per drawing 100%. Production time: 35days after confirmation;

FAQ:

How to check the material quality ?

The quick method is to fold raw material by several time and check the final status.

From outside looking, some difference between good one & poor one ?

The rough method is to see the cutting area.

May I have samples firstly before mass production ?

Yes, we have this key step. We will ensure the samples from same grade material and final progressive die. Also we will control the finishing, like plating. For mass production, we order the raw material from one time only, not two times. It will help us a little for size control. As per normal doing method, the size is about 0.02 minus and plus, material in 0.8mm.

If some problem on plastic part, it need correction on size correct from Copper stamping part, is it possible ?

It is possible. but it is not 3 times modification. As we focus one time finishing.

Why choose us?

- We use cutting-edge technology and equipment to ensure precision and accuracy in our metal stamping products.

- Welcome to call to discuss business. Our company will make scientific and reasonable technical solutions for you with first-class service and professional technology according to your needs, so as to save more labor costs for users and provide stable and premium products to them.

- We offer free quotes and consultations to help clients select the best metal stamping products for their needs.

- Over the years, especially since the 18th National Congress of the Communist Party of China, Socket Electrical Stamping parts has closely focused on building Socket Electrical Stamping parts as a strong country, keeping in mind its original mission, making innovations, forging ahead, working hard to provide service guarantees, establishing a good image, winning wide praise, and striving to become the leader of Socket Electrical Stamping parts construction Sheep, strive to create the best Socket Electrical Stamping parts.

- Our team is committed to offering outstanding customer service and support that exceeds our clients' expectations.

- We always adhere to the cultivation of innovative spirit and practical ability of senior professionals, the development of our science and technology culture.

- We believe in building long-term relationships with our clients and providing them with exceptional service.

- According to the career characteristics of employees, we provide a platform to show their talents and emphasize performance-oriented employment.

- We are a Chinese factory that specializes in high-quality metal stamping products and professional services.

- Only those enterprises that continuously create new knowledge, spread new knowledge throughout the organization, and rapidly develop new technologies and new products can be successful.

Hot Tags: socket electrical stamping parts, China socket electrical stamping parts suppliers, manufacturers, factory, Switch And Socket Of Electrical Items, Plastic Galvanization, Brass Electric Power Cord Pin, Brass Stamping Part, Brass Plug Pin, Distribution Box Injection Mold

You Might Also Like

Send Inquiry