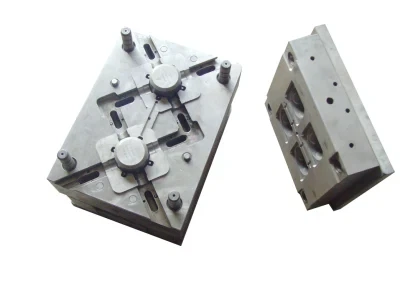

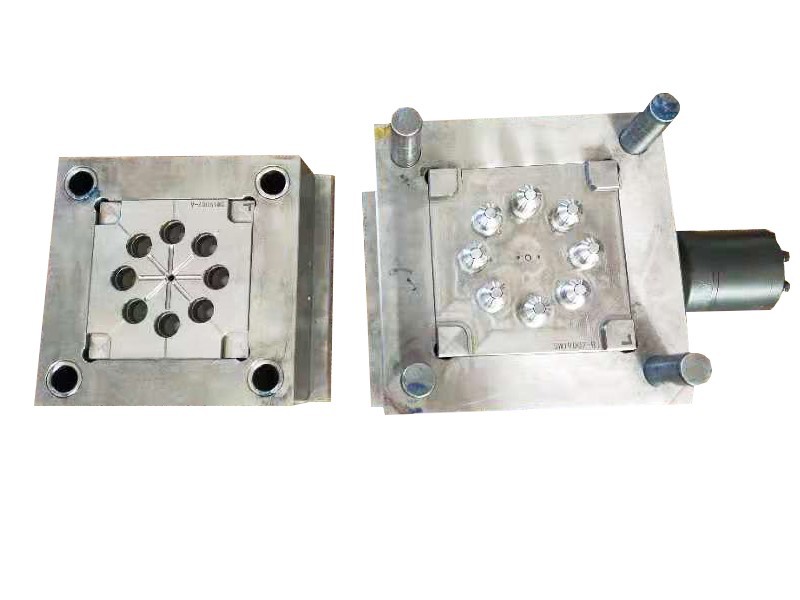

Plastic Injection Mold

Mold Material: 718H, S136 CHINA

Key point on quality of product: weight and finishing on surface

Short description: it is one series model for these product, the mold should be good control on size matching, it is basic and key.

Features

Plastic Injection Mold: High-Quality Manufacturing for Your Business

Welcome to our range of Plastic Injection Molds - an innovative, high-quality product for manufacturers around the world. Based in China, we have a wealth of experience in the production and distribution of molds to businesses in a range of industries.

Our Plastic Injection Molds are among the most expansive, accurate and durable products on the market. We work carefully with customers to tailor our molds to their individual needs, ensuring that they are able to manufacture high-quality products with ease.

Benefits of Our Plastic Injection Molds:

1. Durability and Longevity

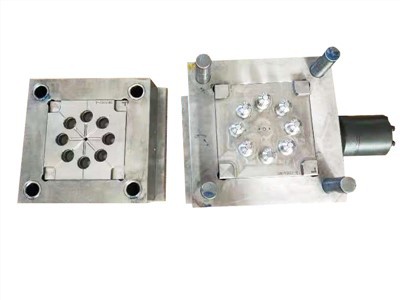

Our Plastic Injection Molds are produced with high-quality materials that are built to withstand rigorous use. They provide a long-lasting, reliable tool that can withstand frequent use without losing any of their properties.

2. Quality

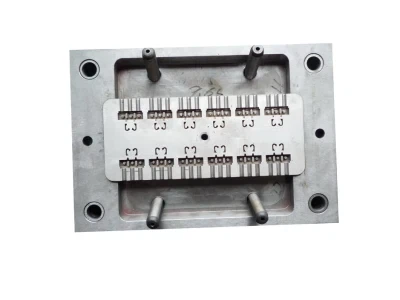

Our molds have micro-injection grinding technology that creates a polished finish, ensuring a perfect injection every time. They also have a high production yield and maintain strict adherence to international standards.

3. Versatility

Our molds have variety of application areas including medical, aviation, automotive, household appliances, stationary, electronics and much more.

4. Affordable Pricing

Our molds are sold at extremely competitive prices, without sacrificing on the quality and accuracy of our products.

Why Choose Plastic Injection Molds?

The ability to create exceptional quality products is dependent on your manufacturing processes. That's where our Plastic Injection Molds come in. They are designed to make manufacturing processes simpler, more efficient and more profitable.

Our molds provide exceptional precision and accuracy, facilitating fast and efficient production of an array of products, from household appliances to automotive parts. They are designed to be versatile, with the ability to adapt to various manufacturing processes, allowing you to achieve an optimal production line for your business.

We pride ourselves on providing top quality service, and we work closely with our clients to ensure that all their product requirements are met. Our team of experts is specially trained to provide professional guidance and advice on the best mold designs for your business needs.

Our Commitment to Quality

We take pride in the quality of our Plastic Injection Molds, and ensure that our molds undergo rigorous testing before they are made available to our customers. Our molds are meticulously crafted with state-of-the-art machinery, using only high-grade materials to achieve superior results.

We are committed to providing the best possible service to our clients. Our focus on efficient production, product accuracy and quality control ensures that our clients receive a product that meets or exceeds their expectations at an affordable price.

Conclusion

Our Plastic Injection Molds offer an ideal solution for businesses looking to streamline their manufacturing processes, and deliver high-quality products at scale. As industry experts in China, we are confident that we can meet and exceed all your mold manufacturing needs - from top quality products to competitive pricing, to top-notch customer service.

We are committed to our customers and to manufacturing world-class products, and we look forward to working with you to help bring your business to a new level of efficiency and success. Contact us today for more information about our Plastic Injection Molds, and let us help you revolutionize your production process.

Plastic injection mold Feature:

1. Customizability: Injection molds can be designed to create parts with complex shapes, high precision, and intricate details. This means that the molds can be customized to meet specific manufacturing requirements.

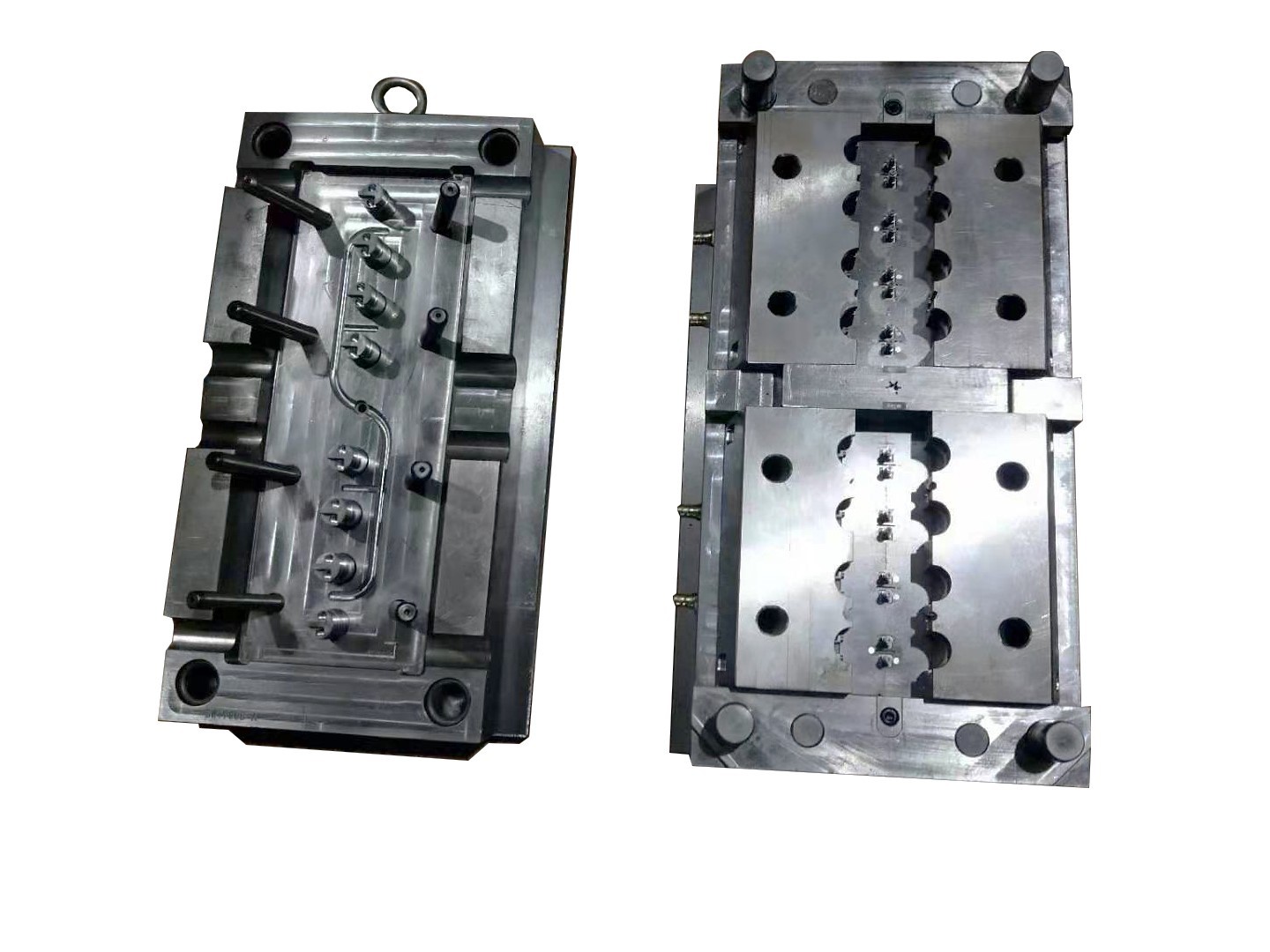

2. High production rates: Once the mold is set up, the plastic injection molding process can be automated, which allows for high production rates and consistent quality output.

3.Wide range of materials: it can be used with a wide variety of plastic materials, including thermoplastics, thermosets, and elastomers. This makes it a versatile manufacturing process that can accommodate different types of products.

4.Cost-effective: it can be a cost-effective manufacturing process, especially for high volume production. The initial cost of creating the mold may be high, but the cost per unit decreases as the volume of production increases.

5.Minimal waste: Injection molding generates minimal waste since excess material can be recycled and used in future production runs.

6.Surface finish: The surface finish of plastic injection molded parts can be customized to achieve different textures and finishes, from smooth and glossy to matte and textured.

7.Design flexibility: Injection molding allows for design flexibility since the mold can be modified to accommodate changes in the design of the product.

We have our own injection molding machine and press. It is for trial confirmation and shipping confirmation. Also, confirm and adjust the quality of molded products and pressed products to provide the high-quality mold.

Why choose us?

- Our products are designed and manufactured with utmost precision to ensure flawless results.

- Our standard and reasonable sales price and warm and considerate after-sales service are deeply trusted by consumers. Welcome customers to order!

- By using superior materials, we ensure that our Plastic Injection Moulding products are durable and long-lasting.

- We constantly improve the cost performance to maintain the competitive advantage of our main Plastic Injection Mold in the market, and constantly develop application fields to maintain the leading position of our core products in the market.

- We offer customized Plastic Injection Moulding products and services to meet the exact needs and specifications of our customers.

- In addition to focusing on building our own brand, our company has become a strategic partner of several companies, hoping to make progress together.

- As a leading supplier and manufacturer, we are committed to providing our customers with the best possible prices.

- Each of our products has tracking and archive records to ensure timely service to customers.

- Our Plastic Injection Moulding services are customized to meet the unique requirements of our clients.

- We regard outstanding products, high quality, and satisfying service as the company's quality policy, which runs through all the work of development, sales, management and service.

Hot Tags: plastic injection mold, China plastic injection mold suppliers, manufacturers, factory, Brass Electrical Component, Metal Stamping, E27 Injection Mold, Plastic Injection Moulding, Metal Electrical Parts, Terminal Block Accessories Brass

No Information

You Might Also Like

Send Inquiry