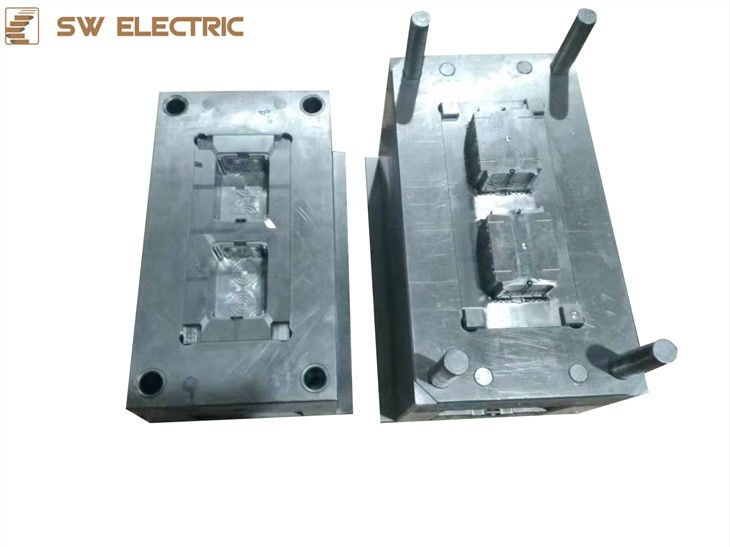

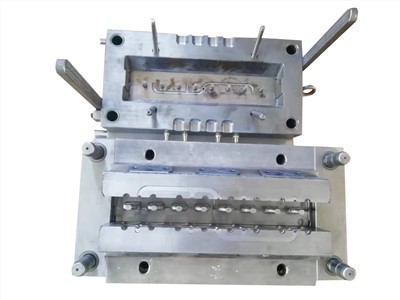

Wiring Device Injection Mold

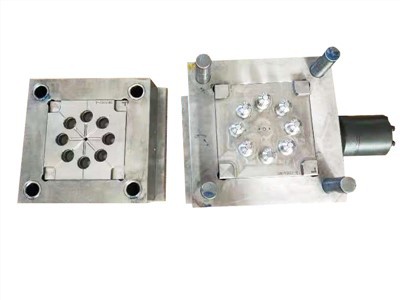

Mold Material: H13, S136, 718H, 1.2836. P20

Key point on quality of product: most material in ABS, PC for wiring device. The surface must be good shinning

Features

Introduction:

As a leading manufacturer of wiring devices in China, we are proud to introduce our latest innovation – the Wiring Device Injection Mold. This product is designed to cater to the needs of merchants outside of China who require high-quality and durable wiring devices to fulfill the demands of their customers. With years of experience in the industry, we have refined our manufacturing process to create a product that is not only reliable and efficient but also cost-effective.

Product Features:

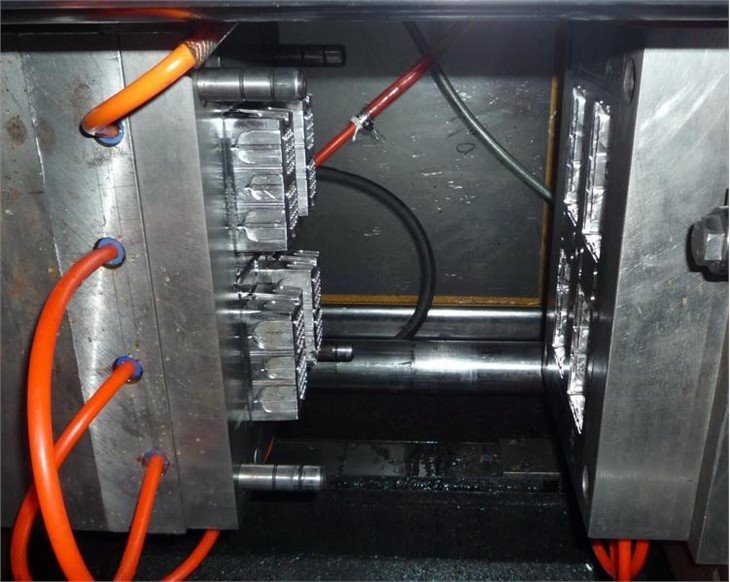

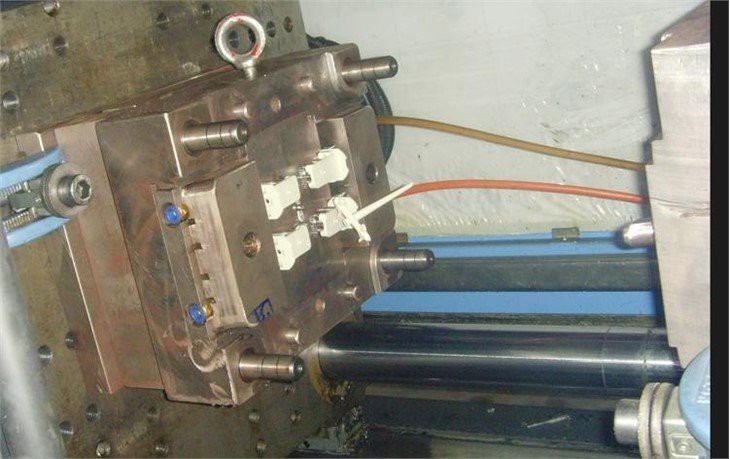

1. High Precision: Our wiring device injection mold is designed with precision in mind. We use computer-aided manufacturing (CAM) and computer-aided design (CAD) to create molds that are accurate to the nearest micron. This ensures that our products fit perfectly and function smoothly.

2. Durability: Our injection mold is made from high-quality materials to ensure that it can withstand even the harshest working conditions. We use materials that are resistant to wear and tear, such as steel and aluminum. This means that our product lasts longer than others on the market, and your customers will appreciate the durability and stability of their wiring devices.

3. Customization: We understand that every customer has unique requirements. That's why we offer customization services to ensure that our products meet your exact specifications. Our experienced engineers will work closely with you to design a mold that fits your needs, whether you need a specific shape, size, or configuration.

4. Cost-effective: We strive to offer our customers the best possible value for their money. Our wiring device injection mold is priced competitively, without compromising on quality. We believe that our product should be affordable for both small and large businesses, so we offer bulk pricing discounts and flexible payment options.

5. Fast turnaround time: We understand that time is of the essence in the business world. That's why we offer fast turnaround times for our products. Once you place your order, our team works quickly to manufacture and ship your product. We use reliable and efficient shipping methods to ensure that your product arrives on time.

Conclusion:

If you're looking for high-quality and reliable wiring devices for your customers, look no further than our Wiring Device Injection Mold. With our commitment to quality, durability, customization, and affordability, we are confident that our product will exceed your expectations. Contact us today to discuss how we can help meet your needs and grow your business.

Mold Material: H13, S136, 718H, 1.2836. P20

Key point on quality of product: most material in ABS, PC for wiring device. The surface must be good shinning

Short description: good looking and good structure, reduce the sliding part as less as possible. For these items, normal it comes with repeat mold. New mold should be improved based on old one. From cooling system to finishing

Wiring device injection mold is a specialized tool used in the manufacturing of electrical wiring devices such as plugs, sockets, switches, and other related products. The mold is designed to shape the raw material, usually plastic, into the desired form by injecting molten plastic under high pressure into the mold cavity. The resulting product is uniform in shape and size, with precise details and smooth finishes. Wiring device injection molds are critical to the production of electrical components, as they allow for efficient and consistent manufacturing of high-quality products. These molds are typically made of high-grade steel or aluminum to withstand the extreme heat and pressure of the injection molding process and can produce a high volume of products in a short amount of time, making them essential to the electrical manufacturing industry.

FAQ:

How many shot from mold design ?

Normally, it is design for 1 million shot. For this working life, it is from material character. In other word, the real running will come with difference. As if the mold receive well and professional maintenance. The mold life is more. If failed, the life time will be less.

Why the price comes big difference for same product ?

Generally, it is from material, finishing, design. Also experience. As mold is special, not from mass production. But we have to use the standard part from top brand company. LIKE DME, HASSCO, LKM. Also some key part should be finished from good machine.

Why choose us?

- We are committed to maintaining a safe working environment for our employees and clients during Plastic Injection Moulding production.

- We take the initiative, continue to explore and surpass, seek common ground while reserving differences, and continue to improve and develop.

- We use the best materials available in our Plastic Injection Moulding processes to ensure that our products are of superior quality.

- The company adheres to the "people-oriented" talent management concept, and has developed a standardized, unified, fair and reasonable staff compensation system with regional competitiveness in the same Wiring Device Injection Mold industry.

- We offer a range of Plastic Injection Moulding services to cater to the diverse needs of our customers.

- The unified core values and rich cultural life not only enhance the cohesion and team spirit of the enterprise, but also make the core competitiveness of the enterprise further enhanced, forming a thriving and positive scene within the group.

- We maintain the highest level of ethical standards in our Plastic Injection Moulding production processes.

- We are committed to leading the development of the industry, acting as a pioneering force, and constantly dedicating ourselves to high-quality products.

- We take pride in offering exceptional Plastic Injection Moulding services to our clients.

- On the basis of actively participating in international competition, we constantly grasp the pulse of market development, seek economic strategic alliances, and develop and progress together with global partners.

Hot Tags: wiring device injection mold, China wiring device injection mold suppliers, manufacturers, factory, Brass Electrical Pins, Wiring Device Metal Part, Holder With Thread Injection Mold, Lamp Holder Injection Mold, Brass Stamping Part, Socket Precise Injection Mold

No Information

You Might Also Like

Send Inquiry