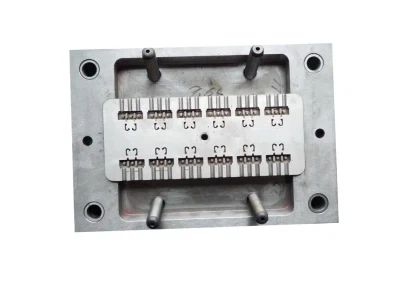

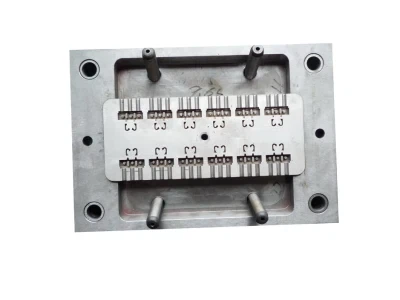

Holder with Thread Injection Mold

Mold Material: HRC48 H13;

Key point on quality of product: injection gate. We also should consider the raw material grade. As if some times the real injection material is 2nd grade PA or not 100% pure, we have to change the injection dot gate to be direct injection gate

Features

Introducing the Holder with Thread Injection Mold – The Ultimate Solution for Your Business

Are you tired of constantly worrying about the security of your products or equipment during transportation or storage? Are you in search of a durable and reliable solution that can help you keep your things organized and secure? Look no further as we introduce the Holder with Thread Injection Mold – an innovative and multifunctional product that is engineered to cater to all your storage and organization needs.

Our Holder is the perfect solution for businesses that deal with a variety of products, as it offers a versatile and adjustable storage model that can be customized according to your specific requirements. It is made of high-quality materials and an advanced thread injection mold that ensures durability, long-lasting use, and a smooth finish.

With our Holder, you can be confident that your products or equipment are safe from damage or breakage, which can harm your business's bottom line. It features a robust structure that can withstand high impact or pressure, making it an ideal choice to hold even the heaviest of items securely.

One aspect that makes the Holder stand out is the unique customization features it offers. It comes with an adjustable sliding mechanism that allows you to modify the height and width of the product according to your specific needs. This ensures that you can use our product with a wide range of items, making it an incredibly versatile option that can help you save money and space.

Another primary feature of our Holder is its mode of operation. It is incredibly user-friendly, with an easy-to-use thread mechanism that ensures smooth operation and prevents accidental drops. The design ensures that you can use the product with minimal effort, all the while ensuring the optimum level of security and protection for your inventory.

Apart from its numerous benefits, the Holder is also an eco-friendly product that is crafted with the environment in mind. We use sustainable materials and manufacturing processes to ensure that our product is eco-friendly, reducing our carbon footprint in the process.

The Holder is an ideal choice for a broad range of businesses, including those in the electronics, automotive, and food industries. It is versatile in use, sturdy in construction, and offers a great deal of value for both short and long-term storage solutions.

To conclude, the Holder with Thread Injection Mold is an excellent product that offers a range of benefits, including durability, security, versatility, ease of use, and eco-friendliness. Our product is designed to cater to the needs of businesses looking for a dependable and customizable storage solution that can help them increase productivity, save space, and protect their products from damage. Order the Holder today and give your business the protection it deserves.

Short description: product is with thread, like cap for bottle. the material is hard, like PA WITH 30% glassfibre

Mold Material: HRC48 H13;

Key point on quality of product: injection gate. We also should consider the raw material grade. As if some times the real injection material is 2nd grade PA or not 100% pure, we have to change the injection dot gate to be direct injection gate

| PRODUCT NAME | COLLAPSIBLE CORE MOLD DESIGN FOR INTERNAL UNDERCUT INJECTION MOLDING |

| Mould base | LKM,HASCO.ETC. |

| Mould material | S136/2344/718/738/NAK80/P20 |

| Plastic material | PVC/PA66/PC/PE/POM/PMMA/ABS/TPU/TPE/PE/PP.ETC. |

| Mould life | 100,000-300,000shots |

| Cavity | Single/Multi Cavity |

| Package | Standard wooden case and carton or according requirement |

| Lead time | 25-45days |

| Certification | ISO9001:2015 |

Quality:

Long time working life for mold, due to PA 30% firbre, the iron will be off little by little. After the plastic flash come, the mold spare parts should be replaced

Quality control:

Have weekly maintenance on inside moving part. It should be with more grease. Also when mold running, pls have more care for sound. It should be like normal.

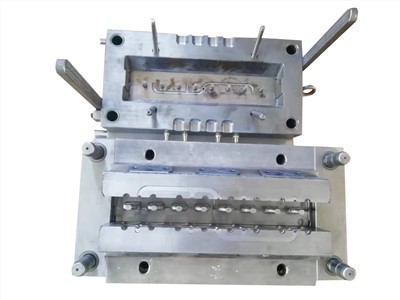

Mold details:

The mold design is via oil hydraulic motor, also sometimes, we finish it as per HASSCO standard part. But it is for PP material working. The working life will be 1 million shot. If it is for pa material, the life time will be reduced about 40% or more. The injection cost will be high for complete product.

Mold finishing and packaging:

If the structure is similar HASCO Standard part, each inside part should be with precise Wire cut. In this case, the gap between each part will be 0.005mm. For PP, the material is out for gap 0.02mm. So it is good for running.

Why choose us?

- We use advanced production techniques to ensure that our Plastic Injection Moulding products are of the highest quality.

- We plan to create a vibrant and competitive brand enterprise, and cooperate with customers abroad with a pragmatic attitude to create a better tomorrow.

- We are committed to ensuring that every Plastic Injection Moulding product we produce meets our customers' specifications.

- In the future, we will maintain our strategic determination, grasp the rhythm of our strategy and push forward steadfastly.

- We offer customized Plastic Injection Moulding products and services to meet the exact needs and specifications of our customers.

- Our company advocates peace as the value, with a tolerant professional mentality, harmonious pursuit of values, to achieve a win-win situation between enterprises and customers, and the harmonious development of enterprises and employees.

- We maintain the highest level of ethical standards in our Plastic Injection Moulding production processes.

- Our company is a large-scale enterprise specialized in producing Holder with Thread Injection Mold, integrating R&D, design, manufacturing and marketing.

- We offer end-to-end Plastic Injection Moulding solutions, from design and development to production and delivery.

- Our company is a national high-tech enterprise with an experienced R&D and design team and production management team, which can meet the increasing quality requirements of customers, and is also conducive to the company to keep up with market trends and fashion trends.

Hot Tags: holder with thread injection mold, China holder with thread injection mold suppliers, manufacturers, factory, Metal Electrical Parts, Brass Plug Pins Flat, Wiring Device Injection Mold, Precision Injection Mold Plug, Switch And Socket Of Electrical Items, Phosphor Stamping Part

You Might Also Like

Send Inquiry